REFERENCES

- [1] J. Starke E.A. and J. Staley, (1996) “Application of modern aluminum alloys to aircraft" Progress in Aerospace Sciences 32(2-3): 131–172. DOI: 10.1016/0376-0421(95)00004-6.

- [2] G. Mathers. The welding of aluminium and its alloys. Elsevier, 2002.

- [3] H. Liu, W. Zhu, H. Dong, and Y. Ke, (2017) “A helical milling and oval countersinking end-effector for aircraft assembly" Mechatronics 46: 101–114. DOI: 10.1016/j.mechatronics.2017.07.004.

- [4] A. Lacombe, Y. Landon, M. Paredes, C. Chirol, and A. Benaben, (2021) “Influence of the Hole Surface Integrity on the Fatigue Strength of an Aluminium Drilled Part" Lecture Notes in Mechanical Engineering: 34–40. DOI: 10.1007/978-3-030-70566-4_7.

- [5] Z. Yijin. “Research on automatic drilling riveting technology of aluminum-lithium alloy on largeaircraft”. In: cited By 0. 2020, 280–283. DOI: 10.1109/ICEDME50972.2020.00070.

- [6] K. Giasin, A. Hodzic, V. Phadnis, and S. Ayvar-Soberanis, (2016) “Assessment of cutting forces and hole quality in drilling Al2024 aluminium alloy: experimental and finite element study" The International Journal of Advanced Manufacturing Technology 87(5): 2041–2061. DOI: 10.1007/s00170-016-8563-y.

- [7] M. Uddin, A. Basak, A. Pramanik, S. Singh, G. M. Krolczyk, and C. Prakash, (2018) “Evaluating Hole Quality in Drilling of Al 6061 Alloys" Materials 11(12): DOI: 10.3390/ma11122443.

- [8] G. Le Coz, M. Jrad, P. Laheurte, and D. Dudzinski, (2017) “Analysis of local cutting edge geometry on temperature distribution and surface integrity when dry drilling of aeronautical alloys" International Journal of Advanced Manufacturing Technology 93(58): 2037–2044. DOI: 10.1007/s00170-017-0671-9.

- [9] S. Xiang, (2017) “Influence analysis of processing parameters on swarf and hole features in drilling aluminum alloy lamella" Manufacturing Technology & Machine Tool 11: 132–136.

- [10] D. Yuan, S. Lei, W. Zhao, and Y. Yang, (2018) “Experimental study on the drilling burr height of aerospace aluminium alloy sheet" Manufacturing Technology & Machine Tool 6: 127–130.

- [11] A. Abdelhafeez, S. Soo, D. Aspinwall, A. Dowson, and D. Arnold. “Burr formation and hole quality when drilling titanium and aluminium alloys”. In: 37. cited By 60. 2015, 230–235. DOI: 10.1016/j.procir.2015.08.019.

- [12] C. Y. Seif, I. S. Hage, R.-M. S. Hage, and R. F. Hamade, (2022) “Exploiting the drill cutting lip to quantify the contributions of process parameters to cutting pressures - a response surface analysis" International Journal of Manufacturing Research 17(1): 95–125. DOI: 10.1504/IJMR.2022.121602.

- [13] L. Sun, H. Gao, B.Wang, Y. Bao, M.Wang, and S. Ma, (2020) “Mechanism of reduction of damage during helical milling of titanium/CFRP/aluminium stacks" International Journal of Advanced Manufacturing Technology 107(11-12): 4741–4753. DOI: 10.1007/s00170-020-05177-1.

- [14] A. Akhavan Farid, S. Sharif, and M. Idris, (2021) “Performance and wear mechanisms of uncoated, TiAlN, and AlTiN-coated carbide tools in high-speed drilling of Al-Si alloy" International Journal of Advanced Manufacturing Technology 113(9-10): 2671–2684. DOI: 10.1007/s00170-021-06663-w.

- [15] L. Sobotova, M. Badida, M. Moravec, A. Badidova, and A. Maslejova, (2020) “New findings in the field of thermal drilling of aluminum alloys" Materials 13(21): 1–17. DOI: 10.3390/ma13215007.

- [16] I. A. Popan, A. I. Popan, A. Carean, D. Fratila, and A. Trif. “Study on chip fragmentation and hole quality in drilling of aluminium 6061 alloy with high pressure internal cooling”. In: MATEC Web of Conferences. 299. EDP Sciences. 2019, 04014.

- [17] A. Sifa, D. Suwandi, T. Endramawan, and A. Rachman. “Performance of fan chips on drilling aluminium process”. In: IOP Conference Series: Materials Science and Engineering. 1098. 6. IOP Publishing. 2021,062081.

- [18] A. Sandeep Reddy, S. Ajay Kumar, and T. Jagadesh, (2020) “The Influence of graphite, MOS2 and Blasocut lubricant on hole and chip geometry during peck drilling of aerospace alloy" Materials Today: Proceedings 24: 690–697. DOI: 10.1016/j.matpr.2020.04.323.

- [19] M. Aamir, M. Tolouei-Rad, K. Giasin, and A. Vafadar, (2020) “Machinability of Al2024, Al6061, and Al5083 alloys using multi-hole simultaneous drilling approach" Journal of Materials Research and Technology 9(5):10991–11002.

- [20] M. Aamir, K. Giasin, M. Tolouei-Rad, and A. Vafadar, (2020) “A review: drilling performance and hole quality of aluminium alloys for aerospace applications" Journal of Materials Research and Technology 9(6): 12484–12500. DOI: 10.1016/j.jmrt.2020.09.003.

- [21] F. Veiga, A. Suárez, A. Del Val, M. Penalva, and L. de Lacalle, (2020) “Evaluation on advantages of low frequency assisted drilling (LFAD) aluminium alloy Al7075" International Journal of Mechatronics and Manufacturing Systems 13(3): 230–246. DOI: 10.1504/IJMMS.2020.111283.

- [22] L. Wei and D. Wang, (2020) “Effect of ultrasoundassisted vibration on Ti-6Al-4V/Al2024-T351 laminated material processing with geometric tools" International Journal of Advanced Manufacturing Technology 106(1-2): 219–232. DOI: 10.1007/s00170-019-04637-7.

- [23] B. Ozcelik and E. Bagci, (2006) “Experimental and numerical studies on the determination of twist drill temperature in dry drilling: A new approach" Materials and Design 27(10): 920–927. DOI: 10.1016/j.matdes.2005.03.008.

- [24] W. Zhang and P. K. Zhang, (2011) “Axial Vibration Drilling Machining Simulation of 2A12 based on Deform" Equipment Manufacturing Technology 1: 20–217.

- [25] B. Li, S. Liu, X. Tian, F. Gao, and Z. Zhang, (2012) “Drilling simulation on carbon fiber reinforced plastics and aluminum laminated composite" Advanced Materials Research 490-495: 3281–3285. DOI: 10.4028/www.scientific.net/AMR.490-495.3281.

- [26] M. Montoya, M. Calamaz, D. Gehin, and F. Girot, (2014) “Numerical simulation of workpiece thermal field in drilling CFRP/aluminum alloy" Key Engineering Materials 611-612: 1226–1235. DOI: 10.4028/www.scientific.net/KEM.611-612.1226.

- [27] M. Daoud, J. Chatelain, and A. Bouzid, (2015) “Effect of rake angle on Johnson-Cook material constants and their impact on cutting process parameters of Al2024-T3 alloy machining simulation" International Journal of Advanced Manufacturing Technology 81(9-12): 1987–1997. DOI: 10.1007/s00170-015-7179-y.

- [28] P. Pawar, R. Ballav, and A. Kumar, (2016) “Finite element method broach tool drilling analysis using explicit dynamics ansys" International Journal of Modern Manufacturing Technologies 8(2): 54–60.

- [29] D. Wu, S. Huang, Y. Gao, Y. Dong, and X. Ma, (2017) “Predictive model for the interlayer burr height during drilling of stacked aluminum plates" Qinghua Daxue Xuebao/Journal of Tsinghua University 57(6): 591–596 and 603. DOI: 10.16511/j.cnki.qhdxxb.2017.26.024.

- [30] S. Dehghan, M. Ismail, M. Ariffin, B. Baharudin, and S. Sulaiman, (2017) “Numerical simulation on friction drilling of aluminum alloy: Numerische Simulation des Reibbohrens von Aluminiumlegierungen" Materialwissenschaft und Werkstofftechnik 48(3): 241–248. DOI: 10.1002/mawe.201600768.

- [31] H. Paktinat and S. Amini, (2017) “Ultrasonic assistance in drilling: FEM analysis and experimental approaches" International Journal of Advanced Manufacturing Technology 92(5-8): 2653–2665. DOI: 10.1007/s00170-017-0285-2.

- [32] L. H. Ma, (2017) “Finite element analysis of 3D drilling of 7055 aluminium alloy based on deform-3d" Ordnance Material Science and Engineering 40(5): 46–50.

- [33] S. T. Huang, P. Zhang, and H. T. Wang, (2018) “Finite Element Analysis on Thrust Force of Carbon Fiber Reinforced Plastic and Aluminum Stacks Composite Ma-terial Drilling" Tool Engineering 52(5): 63–68.

- [34] S. Huang, H. T.Wang, and P. Zhang, (2019) “Finite element analysis on drilling defects of carbon fiber reinforced plastic and aluminum stacks" Journal of Materials Science and Engineering 37: 493–500.

- [35] N. Ya¸sar, (2019) “Thrust force modelling and surface roughness optimization in drilling of AA-7075: FEM and GRA" Journal of Mechanical Science and Technology 33(10): 4771–4781. DOI: 10.1007/s12206- 019-0918-5.

- [36] R. Sreenivasulu, S. Rao, et al. “Some Investigations on Drilling of Aluminium Alloy from FEA-Based Simulation Using DEFORM-3D”. In: Advances in Simulation, Product Design and Development. Springer, 2020, 3–15.

- [37] S. Reddy and S. Chalamalasetti, (2021) “Optimization of drilling parameters during machining of Al-Mg-Si alloys by Taguchi method coupled with grey relational analysis and validated by FEA based deform - 3D" Strojnicky Casopis 71(2): 221–238. DOI: 10.2478/scjme-2021-0032.

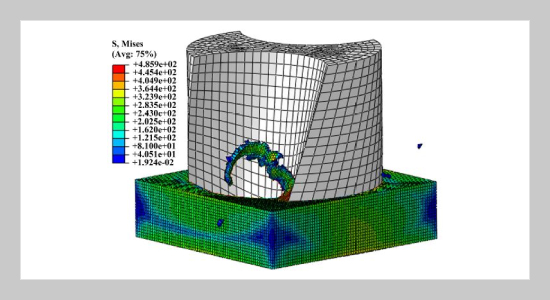

- [38] A. Tzotzis, C. García-Hernández, J.-L. Huertas-Talón, and P. Kyratsis, (2020) “FEM based mathematical modelling of thrust force during drilling of Al7075-T6" Mechanics and Industry 21(4): DOI: 10.1051/meca/2020046.

- [39] A. Tzotzis, A. Markopoulos, N. Karkalos, D. Tzetzis, and P. Kyratsis. “FEM based investigation on thrust force and torque during Al7075-T6 drilling”. In: 1037. 1. cited By 2. 2021. DOI: 10.1088/1757-899X/1037/1/012009.

- [40] I. Boldyrev and D. Topolov, (2021) “Twist Drilling FEM Simulation for Thrust Force and Torque Prediction" Lecture Notes in Mechanical Engineering: 946–952. DOI: 10.1007/978-3-030-54817-9_109.

- [41] G. Johnson and W. Cook, (1985) “Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures" Engineering Fracture Mechanics 21(1): 31–48. DOI: 10 . 1016/0013 -7944(85)90052-9.

- [42] S. Kouadri, K. Necib, S. Atlati, B. Haddag, and M. Nouari, (2013) “Quantification of the chip segmentation in metal machining: Application to machining the aeronautical aluminium alloy AA2024-T351 with cemented carbide tools WC-Co" International Journal of Machine Tools and Manufacture 64: 102–113. DOI: 10.1016/j.ijmachtools.2012.08.006.