S. Jeyanthi This email address is being protected from spambots. You need JavaScript enabled to view it.1 and J. Janci Rani1 1Department of Automobile Engineering, MIT, Anna University, Chennai, India

Received:

September 14, 2011

Accepted:

December 2, 2011

Publication Date:

September 1, 2012

Download Citation:

||https://doi.org/10.6180/jase.2012.15.3.08

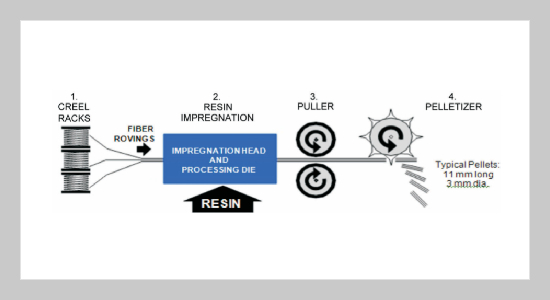

Natural fibers have recently become attractive to automotive industry as an alternative reinforcement for glass fiber reinforced thermoplastics. The best way to increase the fuel efficiency without sacrificing safety is to employ fiber reinforced composite materials in the body of the cars so that weight reduction can be achieved. Designing the structures with the focus on improvement aspects is very important in the automotive industry. The goals are to increase the performance of the beams and also to find the solution to reduce the cost of beams hence able to reduce the production cost. The latest thermo plastic developments have resulted in higher material properties and more possibilities in the design of bumper beams. However the use of steel, Aluminum, Glass mat thermoplastics (GMT), sheet metal components (SMC) Bumpers becomes at higher cost than long fiber reinforced thermoplastics. This research is focused on partially eco-friendly hybrid long fiber reinforced thermo plastics with natural kenaf fiber to enhance the desired mechanical properties for car bumper beams as automotive structural components. A specimen without any modifier is tested and compared with a typical bumper beam material called LFRT. the results indicate that some mechanical properties such as tensile strength, young’s modulus, flexural strength an flexural modulus are more advantages to LFRT, the new material also must improve the ability to absorb more impact load and increase the protection of the front car component.ABSTRACT

Keywords:

Bumper Beam, LFRT, GMT, SMC, Kenaf Fiber, Hybrid

REFERENCES