P. Kulandaivelu This email address is being protected from spambots. You need JavaScript enabled to view it.1 and P. Senthil Kumar2 1Department of Mechanical Engineering, K.S. Rangasamy College of Technology, Tiruchengode, India

2Department of Mechanical Engineering, K.S.R. College of Engineering, Tiruchengode, India

Received:

July 19, 2011

Accepted:

December 2, 2011

Publication Date:

September 1, 2012

Download Citation:

||https://doi.org/10.6180/jase.2012.15.3.07

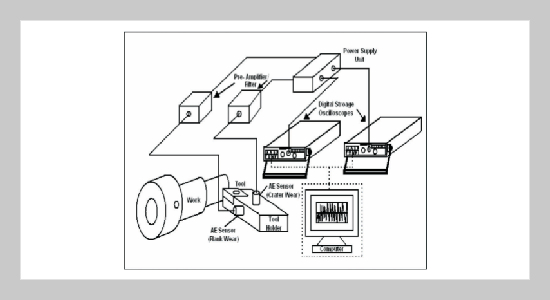

This paper deals with the crater wear characteristics of coated carbide tool inserts during dry turning of steel workpieces. Wear also occurs as a result of abrasion, as well as cracking and attrition, with the latter leading to the wearing through of the coating on the rake face under low speed conditions. When moderate speeds and feeds are used, the coating remains intact throughout the duration of testing. Wear mechanism maps linking the observed wear mechanisms to machining conditions are presented for the first time. These maps demonstrate clearly that transitions from one dominant wear mechanism to another may be related to variations in measured tool wear rates. Comparisons of the present wear maps with similar maps for uncoated carbide tools show that TiC coatings dramatically expand the range of machining conditions under which acceptable rates of tool wear might be experienced. However, the extent of improvement brought about by the coatings depends strongly on the cutting conditions, with the greatest benefits being seen at higher cutting speeds and feed rates. Among the available methods, tool condition monitoring using Acoustic Emission Techniques (AET) is an emerging one. Hence, the present work is carried out to study the stability, applicability and relative sensitivity of AET in tool condition monitoring in turning. Attempts were made using Adaptive Neuro Fuzzy Inference System (ANFIS) tool to predict the possibilities of establishing the correlation between the crater wear and the variation of acoustic emission parameters like average value, RMS value and area or energy of the signal.ABSTRACT

Keywords:

Acoustic Emission Parameters, Crater Wear, Stress Wave, Adaptive Neuro Fuzzy Inference System

REFERENCES