1Applied Mechanics Department Birla Institute of Technology Mesra, Ranchi−835215, India

2Production Engineering Department Birla Institute of Technology Mesra, Ranchi−835215, India

Received:

August 19, 2003

Accepted:

October 7, 2003

Publication Date:

March 1, 2004

Download Citation:

||https://doi.org/10.6180/jase.2004.7.1.08

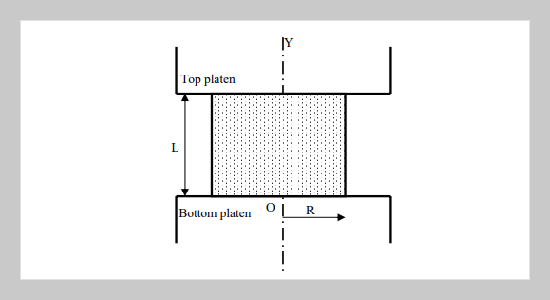

The paper reports an investigation into the forging of solid powder circular disc with large slenderness ratio, between two flat dies. The deformation pattern during the operation is influenced by many factors, which interact with each other in a complex manner. The decisive factors are the interfacial conditions, initial relative density of the preform and the geometry of the preform. An attempt has been made for the determination of the die pressures developed during the forging of a circular disc with large slenderness ratio using an upper bound approach. The results so obtained are discussed critically to illustrate the interaction of various process parameters involved and are presented graphically.ABSTRACT

Keywords:

Slenderness Ratio, Preform, Interfacial Friction Law

REFERENCES