Yu-Tang Chen1,2, Shung-Wen Kang This email address is being protected from spambots. You need JavaScript enabled to view it.1, Wen-Chian Tuh1 and Tsung-Hsin Hsiao1 1Department of Mechanical and Electro-Mechanical Engineering Tamkang University Tamsui, Taiwan 251, R.O.C.

2Department of Mechanical Engineering De Lin Institute of Technology Tuchen, Taiwan 236, R.O.C.

Received:

February 17, 2003

Accepted:

October 29, 2003

Publication Date:

March 1, 2004

Download Citation:

||https://doi.org/10.6180/jase.2004.7.1.03

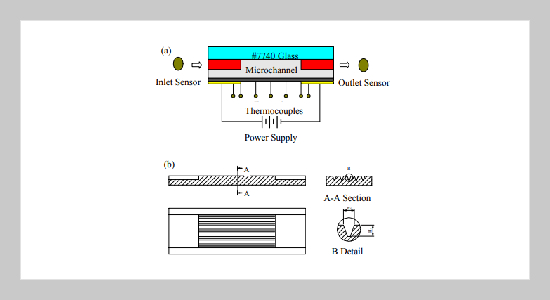

Due to the high performance of electronic components, the heat generation is increasing dramatically. Heat dissipation becomes a significant issue in efficiency promotion and stable operation. Silicon based microchannel heat sink fabricated using semiconductor production technique plays an important role in cooling devices. Experimental tests and theoretical analyses were conducted to investigate the characteristics of fluid flow and heat transfer in microchannel heat sink in this paper, especially in the mechanism of bubble nucleation. Methanol was used as the working fluid and flowed through microchannels with different hydraulic diameters ranging from 57−267 µm in the experiments. Experimental results of flow characteristics indicated that the flow behavior was in the laminar regime when Re = 50−850, the phenomena of early transition didn’t exist. The phenomenon shows that the surface roughness, viscosity, and channel geometry have great effects on flow characteristics in microchannels. Experimental results in heat transfer indicted that forced convection in microchannel heat sink exhibited excellent cooling performance, especially in the phase change regime. It will be applied as heat removal and temperature control devices in high power electronic components. When the critical nucleate heat flux condition appeared, flow mechanism changed into fully developed nucleate boiling and accompanied with wall temperature decreased rapidly and pressure drop increased sharply. Experimental results also indicated that the critical bubble size of methanol was between 57−83 µm.ABSTRACT

Keywords:

Microchannel, Mechanism of Bubble Nucleation, Hydraulic Diameters, Critical Nucleate Heat Flux

REFERENCES