Chin Lung Chen This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Fuhua Jen 2 1Electronic Research & Service Organization Industrial Technology Research Institute Jhudong, Taiwan 310, R.O.C.

2Department of Mechanical Engineering Ming Hsin University of Science and Technology Sinfong, Taiwan 304, R.O.C.

Received:

November 22, 2003

Accepted:

January 12, 2004

Publication Date:

March 1, 2004

Download Citation:

||https://doi.org/10.6180/jase.2004.7.1.02

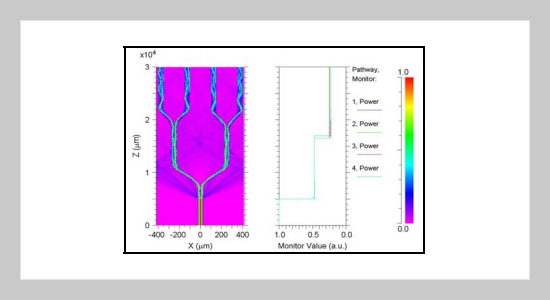

This research focuses on the manufacturing of 1 by 4 multimode polymer splitter. MEMS fabricating process was first adopted for the fabrication of four inches silicon mold insert and then the micro hot embossing technique was applied to the optical class PMMA material for splitters. The BeamPROP™ simulation software was utilized for the design of optimal silicon mold insert. In the analysis of micro hot embossing process, the factorial experiment and Taguchi method were used in order to find the most significant control factor and the optimal combination of micro hot embossing parameters.ABSTRACT

Keywords:

MEMS, Micro Hot Embossing, Polymer Splitter, Taiguchi

REFERENCES