- [1] Y. Liu, J.-P. Yang, H.-M. Xiao, C.-B. Qu, Q.-P. Feng, S.-Y. Fu, and Y. Shindo, (2012) “Role of matrix modification on interlaminar shear strength of glass fibre/epoxy composites" Composites Part B: Engineering 43(1): 95–98. DOI: 10.1016/j.compositesb.2011.04.037.

- [2] P. Franciszczak, K. Kalnin, š, and A. Bł˛edzki, (2018) “Hybridisation of man-made cellulose and glass reinforcement in short-fibre composites for injection moulding– Effects on mechanical performance" Composites Part B: Engineering 145: 14–27. DOI: 10.1016/j.compositesb.2018.03.008.

- [3] N. Guermazi, A. B. Tarjem, I. Ksouri, and H. F. Ayedi, (2016) “On the durability of FRP composites for aircraft structures in hygrothermal conditioning" Composites Part B: Engineering 85: 294–304. DOI: 10.1016/j.compositesb.2015.09.035.

- [4] S. Sakuri, E. Surojo, D. Ariawan, and A. R. Prabowo, (2020) “Experimental investigation on mechanical characteristics of composite reinforced cantala fiber (CF) subjected to microcrystalline cellulose and fumigation treatments" Composites Communications 21: 100419. DOI: 10.1016/j.coco.2020.100419.

- [5] G. Koronis, A. Silva, and M. Fontul, (2013) “Green composites: A review of adequate materials for automotive applications" Composites Part B: Engineering 44(1): 120–127. DOI: 10.1016/j.compositesb.2012.07.004.

- [6] S. Li, T. Zheng, Q. Li, Y. Hu, and B. Wang, (2019) “Flexural and energy absorption properties of natural-fiber reinforced composites with a novel fabrication technique" Composites Communications 16: 124–131. DOI: 10.1016/j.coco.2019.09.005.

- [7] A. Chatterjee, S. Kumar, and H. Singh, (2020) “Tensile strength and thermal behavior of jute fibre reinforced polypropylene laminate composite" Composites Communications 22: 100483. DOI: 10.1016/j.coco.2020.100483.

- [8] N. N. Aimi, H. Anuar, M. Manshor, W. W. Nazri, and S. Sapuan, (2014) “Optimizing the parameters in durian skin fiber reinforced polypropylene composites by response surface methodology" Industrial Crops and Products 54: 291–295. DOI: 10.1016/j.indcrop.2014.01.016.

- [9] A. Putra, M. N. Othman, T. Oliveira, M. Souli, D. H. Kassim, and S. Herawan, (2022) “Waste Durian Husk Fibers as Natural Sound Absorber: Performance and Acoustic Characterization" Buildings 12(8): 1112. DOI: 10.3390/buildings12081112.

- [10] M. C. Lee, S. C. Koay, M. Y. Chan, H. L. Choo, M. M. Pang, P. M. Chou, and K. Y. Tshai, (2020) “Properties of poly (lactic acid)/durian husk fiber biocomposites: Effects of fiber content and processing aid" Journal of Thermoplastic Composite Materials 33(11): 1518–1532. DOI: 10.1177/0892705719831734.

- [11] N. Hegyesi, Y. Zhang, A. Kohári, P. Polyák, X. Sui, and B. Pukánszky, (2019) “Enzymatic degradation of PLA/cellulose nanocrystal composites" Industrial Crops and Products 141: 111799. DOI: 10.1016/j.indcrop.2019.111799.

- [12] K. L. Pickering, M. A. Efendy, and T. M. Le, (2016) “A review of recent developments in natural fibre composites and their mechanical performance" Composites Part A: Applied Science and Manufacturing 83: 98–112. DOI: 10.1016/j.compositesa.2015.08.038.

- [13] G. Gamon, P. Evon, and L. Rigal, (2013) “Twin-screw extrusion impact on natural fibre morphology and material properties in poly (lactic acid) based biocomposites" Industrial Crops and Products 46: 173–185. DOI: 10.1016/j.indcrop.2013.01.026.

- [14] C. Dong, (2020) “Flexural properties of symmetric carbon and glass fibre reinforced hybrid composite laminates" Composites Part C: Open Access 3: 100047. DOI: 10.1016/j.jcomc.2020.100047.

- [15] M. Ayaz, (2018) “Evaluation of the impact and flexural strength of PP/clay/CaCO3/MAPP ternary nanocomposites by application of full factorial design of experiment" Journal of Thermoplastic Composite Materials: 0892705718808566. DOI: 10.1177/0892705718808566.

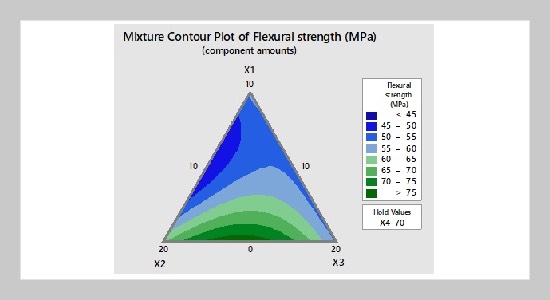

- [16] B. Nadondu, P. Surin, and J. Deeying, (2022) “Multiobjective optimization on mechanical properties of glasscarbon and durian skin fiber reinforced poly (lactic acid) hybrid composites using the extreme mixture design response surface methodology" Case Studies in Construction Materials 17: e01675. DOI: 10.1016/j.cscm.2022.e01675.

- [17] K. L. Pickering, M. A. Efendy, and T. M. Le, (2016) “A review of recent developments in natural fibre composites and their mechanical performance" Composites Part A: Applied Science and Manufacturing 83: 98–112. DOI: 10.1016/j.compositesa.2015.08.038.

- [18] G.-C. Yu, L.-Z. Wu, and L.-J. Feng, (2015) “Enhancing the thermal conductivity of carbon fiber reinforced polymer composite laminates by coating highly oriented graphite films" Materials & Design 88: 1063–1070. DOI: 10.1016/j.matdes.2015.09.096.

- [19] M. Manshor, H. Anuar, M. N. Aimi, M. A. Fitrie, W. W. Nazri, S. Sapuan, Y. El-Shekeil, and M. Wahit, (2014) “Mechanical, thermal and morphological properties of durian skin fibre reinforced PLA biocomposites" Materials & Design 59: 279–286. DOI: 10.1016/j.matdes.2014.02.062.

- [20] natureworksllc. 2023.

- [21] D. C. Montgomery. Design and analysis of experiments. John wiley & sons, 2017.

- [22] I. Minitab. Minitab 17 statistical software. State College: Minitab. 2010.

- [23] J. Lawson and C. Willden, (2016) “Mixture experiments in R using mixexp" Journal of Statistical Software 72: 1–20. DOI: 10.18637/jss.v072.c02.

- [24] I. ASTM, (2017) “Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials" ASTM D790-17:

- [25] I. Tharazi, A. Sulong, N. Muhamad, C. Haron, D. Tholibon, N. Ismail, M. Radzi, and Z. Razak, (2017) “Optimization of hot press parameters on tensile strength for unidirectional long kenaf fiber reinforced polylacticacid composite" Procedia engineering 184: 478–485. DOI: 10.1016/j.proeng.2017.04.150.

- [26] G. Koronis, A. Silva, and S. Foong, (2017) “Predicting the flexural performance of woven flax reinforced epoxy composites using design of experiments" Materials Today Communications 13: 317–324. DOI: 10.1016/j.mtcomm.2017.10.019.

- [27] J. Deeying, K. Asawarungsaengkul, and P. Chutima, (2018) “Multi-objective optimization on laser solder jet bonding process in head gimbal assembly using the response surface methodology" Optics & Laser Technology 98: 158–168. DOI: 10.1016/j.optlastec.2017.07.045.

- [28] K. Maji, D. Pratihar, and A. Nath, (2013) “Experimental investigations and statistical analysis of pulsed laser bending of AISI 304 stainless steel sheet" Optics & Laser Technology 49: 18–27. DOI: 10.1016/j.optlastec.2012.12.006.

- [29] L. Liu, X. Wang, H. Zou, M. Yu, and W. Xie, (2017) “Optimizing synthesis parameters of short carbon fiber reinforced polysulfonamide composites by using response surface methodology" Polymer Testing 59: 355–361. DOI: 10.1016/j.polymertesting.2017.02.013.

- [30] I. Abdulkadir, B. S. Mohammed, M. Liew, and M. Wahab, (2021) “Modelling and multi-objective optimization of the fresh and mechanical properties of self-compacting high volume fly ash ECC (HVFA-ECC) using response surface methodology (RSM)" Case Studies in Construction Materials 14: e00525. DOI: 10.1016/j.cscm.2021.e00525.

- [31] W. Zhang, T. Zhang, Z. Chen, G. Wang, Z. Zhang, L. Hu, et al., (2021) “Design and Test of Pneumatic Cleaning System for Potato Micro-seed Seeding" Journal of Applied Science and Engineering 25(1): 37–48. DOI: 10.6180/jase.202202_25(1).0005.

- [32] C. Homkhiew, T. Ratanawilai, and W. Thongruang, (2014) “The optimal formulation of recycled polypropylene/rubberwood flour composites from experiments with mixture design" Composites Part B: Engineering 56: 350–357. DOI: 10.1016/j.compositesb.2013.08.041.

- [33] M. A. Loubes, S. K. Flores, and M. P. Tolaba, (2016) “Effect of formulation on rice noodle quality: Selection of functional ingredients and optimization by mixture design" LWT-Food Science and Technology 69: 280–286. DOI: 10.1016/j.lwt.2016.01.055.

- [34] M. Assawadithalerd, N. Chollacoop, J. Mungkalasiri, and C. Tongcumpou, (2016) “Optimizing Jatropha biodiesohol composition for a suitable kinematic viscosity by a phase diagram and mixture design" Fuel 164: 134–140. DOI: 10.1016/j.fuel.2015.09.090.

- [35] P. Sungsuk, S. Chayaporn, S. Sunphorka, P. Kuchonthara, P. Piumsomboon, and B. Chalermsinsuwan, (2016) “Prediction of pyrolysis kinetic parameters from biomass constituents based on simplex-lattice mixture design" Chinese Journal of Chemical Engineering 24(4): 535–542. DOI: 10.1016/j.cjche.2016.01.004.

- [36] Y. Arao, T. Fujiura, S. Itani, and T. Tanaka, (2015) “Strength improvement in injection-molded jute-fiberreinforced polylactide green-composites" Composites Part B: Engineering 68: 200–206. DOI: 10.1016/j.compositesb.2014.08.032.

- [37] M. Aslan, M. Tufan, and T. Küçükömero˘glu, (2018) “Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites" Composites Part B: Engineering 140: 241–249. DOI: 10.1016/j.compositesb.2017.12.039.

- [38] A. Pappu, K. L. Pickering, and V. K. Thakur, (2019) “Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding" Industrial Crops and Products 137: 260–269. DOI: 10.1016/j.indcrop.2019.05.040.

- [39] S. K. Das, J. Khanam, and A. Nanda, (2016) “Optimization of preparation method for ketoprofen-loaded microspheres consisting polymeric blends using simplex lattice mixture design" Materials Science and Engineering: C 69: 598–608. DOI: 10.1016/j.msec.2016.07.010.