REFERENCES

- [1] Kenning, D. B. R. and Yan, Y., “Pool Boiling Heat Transfer on a Thin Plate: Features Revealed by Liquid Crystal Thermo Graphy,” Int. J. Heat and Mass Transfer, Vol. 39, No. 15, pp. 3117�3137 (1996). doi: 10. 1016/0017-9310(96)00006-3

- [2] Judd, R. L. and Chopra, A., “Interaction of the Nucleation Processes Occurring at Adjacent Nucleation Sites,” ASME J. of Heat and Transfer, Vol. 115, No. 2, pp. 955�962 (1993). doi: 10.1115/1.2911392

- [3] Dhir, V. K., “Numerical Simulations of Pool-Boiling Heat Transfer,” AIChE Journal, Vol. 47, No. 4, pp. 813�834 (2001). doi: 10.1002/aic.690470407

- [4] Shoji, M. and Takagi, Y., “Bubbling Features from a Single Artificial Cavity,” Int. J. Heat and Mass Transfer, Vol. 44, No. 14, pp. 2763�2776 (2001). doi: 10. 1016/S0017-9310(00)00300-8

- [5] Zhang, L. and Shoji, M., “Nucleation Site Interaction in Pool Boiling on the Artificial Surface,” Int. J. Heat and Mass Transfer, Vol. 46, No. 3, pp. 513�522 (2003). doi: 10.1016/S0017-9310(02)00291-0

- [6] Chatpun, S., Watanabe, M. and Shoji, M., “Nucleation Site Interaction in Pool Nucleate Boiling on a Heated Surface with Triple Artificial Cavities,” Int. J. Heat and Mass Transfer, Vol. 47, No. 14/16, pp. 3583� 3587 (2004). doi: 10.1016/j.ijheatmasstransfer.2003. 11.035

- [7] Chatpun, S., Watanabe, M. and Shoji, M., “Experimental Study on Characteristics of Nucleate Pool Boiling by the Effects of Cavity Arrangement,” Experimental Thermal and Fluid Science, Vol. 29, No. 1, pp. 33�40 (2004). doi: 10.1016/j.expthermflusci.2004.01.007

- [8] Sato, T., Koizumi, Y. and Ohtake, H., “Experimental Study on Fundamental Phenomena of Boiling Using Heat Transfer Surfaces with Well-Defined Cavities Created by MEMS (Effect of Spacing between Cavities),” Trans ASME J. of Heat Transfer, Vol. 30, No. 8, pp. 084501-1�084501-4 (2008). doi: 10.1115/1.2927399

- [9] Sato, T., Koizumi, Y. and Ohtake, H., “Experimental Study on Nucleation Site Interaction During Pool Nucleate Boiling by Using Three Artificial Cavities,” ASME International Mechanical Engineering Congress and Exposition, CD-ROM, IMECE2008-68147 (2008). doi: 10.1115/IMECE2008-68147

- [10] Mikic, B. B. and Rohsenow, W. M., “A New Correlation of Pool-Boiling Data Including the Effect of Heating Surface Characteristics,” Journal of Heat Transfer, Vol. 91, pp. 245�250 (1969). doi: 10.1115/1. 3580136

- [11] Das, A. K., Das, P. K. and Saha, P., “Heat Transfer During Pool Boiling Based on Evaporation from Micro and Macrolayer,” Int. J. Heat Mass Transfer, Vol. 49, pp. 3487�3499 (2006). doi: 10.1016/j.ijheat masstransfer.2006.02.050

- [12] Moghaddam, S. and Kiger, T. K., “Microscale Study of the Boiling Process in Low-Surface-Tension Fluids,” ASME IMECE, IMECE2006-16267, CD-R, (2006). doi: 10.1115/IMECE2006-16267

- [13] Kobayashi, Y., Toyokawa, S. and Araki, T., “Heat and Mass Transfer from Thin Liquid Film in the Vicinity of the Interline of Meniscus,” Thermal Science & Engineering, Vol. 2, No. 1, pp. 45�51 (1994).

- [14] Hu, X. G., Zhao, Y. H., Yan, X. H. Tsuruta, T., “A Novel Micro Cooling System For Electronic Device by Using Micro Capillary Groove Evaporator,” Journal of Enhanced Heat Transfer, Vol. 11, No. 4, pp. 407� 416 (2004). doi: 10.1615/JEnhHeatTransf.v11.i4.180

- [15] Labuntsov, D. A., “Current Theories of Nucleate Boiling of Liquids,” Heat Transfer-Soviet Research, Vol. 7, No. 3, pp. 1�14 (1975).

- [16] Zeng, L. Z., Klausner, J. F. and Mei, R., “A Unified Model for the Prediction of Bubble Detachment Diameters in Boiling Systems-I Pool Boiling,” Int. J. Heat Mass Transfer, Vol. 36, No. 9, pp. 2261�2270 (1993). doi: 10.1016/S0017-9310(05)80111-5

- [17] Zuber, N., “The Dynamics of Vapor Bubbles in Nonuniform Temperature Fields,” Int. J. Heat Mass Transfer, Vol. 2, pp. 83�98 (1961). doi: 10.1016/0017-9310 (61)90016-3

- [18] Mei, R., Chen, W., James, F. and Klausner., “Vapor Bubble Growth in Heterogeneous Boiling-I Formulation,” Int. J. Heat Mass Transfer, Vol. 38, No. 5, pp. 909�919 (1995). doi: 10.1016/0017-9310(94)00196-3

- [19] Zhao, Y. H., Masuoka, T. and Tsuruta, T., “Unified Theoretical Prediction of Fully Developed Nucleate Boiling and Critical Heat Flux Based on a Dynamic Microlayer Model,” Int. J. Heat Mass Transfer, Vol. 45, pp. 3189�3197 (2002). doi: 10.1016/S0017-9310 (02)00022-4

- [20] Thome, J. R., “Boiling in Micro Channels: a Review of Experiment and Theory,” Int. J. Heat Fluid Flow, Vol. 25, pp. 128�139 (2004). doi: 10.1016/j.ijheatfluid flow.2003.11.005

- [21] Pan, K. L. and Chen, Z. J., “Simulation of Bubble Dynamics in a Microchannel Using a Front-Tracking Method,” Comput Mata Appl, Vol. 67, No. 2, pp. 290� 306 (2014). doi: 10.1016/j.camwa.2013.05.001

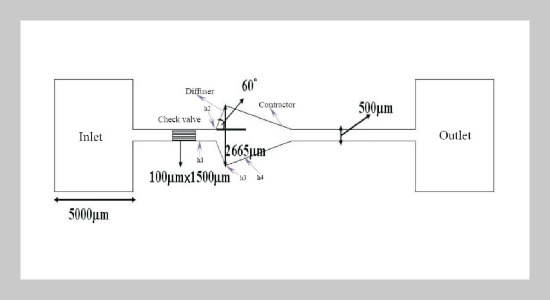

- [22] Tsai, J. H. and Lin, L., “A Thermal-Bubble-Actuated Micronozzle-Diffuser Pump,” Journal of Microelectromechanical Systems, Vol. 11, No. 6, pp. 665�671 (2002). doi: 10.1109/JMEMS.2002.802909

- [23] Danniel, S., Chaudhury, M. K. and Chen, J. C., “Fast Drop Movements Resulting from the Phase Change on a Gradient Surface,” Science, Vol. 291, pp. 633� 636 (2001). doi: 10.1126/science.291.5504.633

- [24] Wasan, D. T., Nikolov, A. D. and Brenner, H., “Fluid Dynamics: Droplets Speeding on Surfaces,” Science, Vol. 291, pp. 605�606 (2001). doi: 10.1126/science. 1058466

- [25] Lee, W. and Son, G., “Numerical Simulation of Bubble Growth and Heat Transfer During Flow Boiling in a Surface-Modified Microchannel,” Heat Transfer Eng, Vol. 35, No. 5, pp. 501�507 (2014). doi: 10.1080/ 01457632.2013.833050

- [26] Talvy, C. A., Shemer, L. and Barnea, D., “On the Interaction between Two Consecutive Elongated Bubbles in a Vertical Pipe,” Int J Multiphas Flow, Vol. 26, pp. 1905�1923 (2000). doi: 10.1016/S0301-9322(00) 00004-5

- [27] Lauga, E. and Brenner, M. P., “Dynamic Mechanisms for Apparent Slip on Hydrophobic Surfaces,” Physical Review E, Vol. 70, pp. 0263111�0263117 (2004). doi: 10.1103/PhysRevE.70.026311

- [28] Ho, T. Y., Ou, S. F., Huang, S. H., Lee, C. N., Ger, L. P., Hsieh, K. S., Cheng, H. Y., Lee, W. Y. and Weng, K. P., “Effect of Flow Rate on Delivery of Bubble Continuous Positive Airway Pressure in an in Vitro Model,” Pediatr Neonatol, Vol. 51, No. 4, pp. 214� 218 (2010). doi: 10.1016/S1875-9572(10)60041-1

- [29] Basaran, O. A., “Nonlinear Oscillations of Viscous Liquid Drops,” T. Fluid Mech, Vol. 241, pp. 169�198 (1992). doi: 10.1017/S002211209200199X

- [30] Kandlikar, S. G., “Controlling Bubble Motion Over Heated Surface through Evaporation Momentum Force to Enhance Pool Boiling Heat Transfer,” Appl Phys Lett, Vol. 102, pp. 0516111�0516115 (2013). doi: 10. 1063/1.4791682

- [31] Wang, C. T., Leu, T. S. and Lai, T. M., “Micro Capillary Pump Loop System for a Cooling High Power Device,” Exp Therm Fluid Sci, Vol. 32, pp. 1090�1095 (2008). doi: 10.1016/j.expthermflusci.2008.01.001