Kuo-Jen Hwang This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Fung-Fu Chen1 1Department of Chemical and Materials Engineering, Tamkang University, Tamsui, Taiwan 251, R.O.C.

Received:

November 21, 2007

Accepted:

October 22, 2008

Publication Date:

March 1, 2009

Download Citation:

||https://doi.org/10.6180/jase.2009.12.1.02

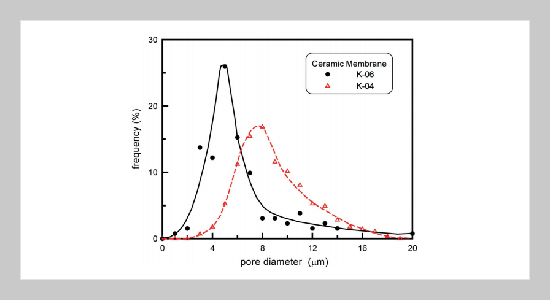

The particle fouling in a submerged membrane filtration system is analyzed by use of membrane blocking models. Two kinds of ceramic membranes made of ZrO2-TiO2, K-04 and K-06, are used in experiments. Their mean pore sizes on the outer surfaces are 8 and 5 µm, respectively. The values of blocking index under various filtration pressures are calculated and discussed. At the initial period of a filtration, the membrane internal blocking is dominant, and the blocking index decreases quickly. The index then suddenly drops to zero at a critical condition and keeps invariably thereafter. The boundary between membrane blocking and particle bridging conditions can be grasped by this blocking index analysis. Membrane blocking occurs only under higher filtration flux or less particle accumulation, while a filter cake may be formed to the contrary conditions. To compare the filtration performances of used membranes, membrane K-04 results in more severe membrane blocking at the initial period of filtration because of more large nominal pores. However, more particles can be continuously held up in the large pores of membrane K-06 due to a little wider pore size distribution and its higher internal porosity. This study provides a useful method to understand the variation of each filtration resistance source during filtration. An increase in filtration pressure leads both resistances due to membrane blocking and cake formation to be increased, as a result, causes to a decrease in the filtration flux. The agreement between calculated filtration resistances and experimental data demonstrates the reliability of the proposed method.ABSTRACT

Keywords:

Membrane Filtration, Particle Fouling, Microfiltration, Blocking Models, Filtration Resistance

REFERENCES