Saranjit Singh This email address is being protected from spambots. You need JavaScript enabled to view it.1, A. K. Jha2 and S. Kumar1 1Department of Production Engineering, Birla Institute of Technology Mesra, Ranchi - 835215, Jharkhand, India

2Department of Mechanical Engineering, Institute of Technology, Banaras Hindu University, Varanasi - 221005, U.P., India

Received:

June 24, 2005

Accepted:

October 11, 2005

Publication Date:

December 1, 2006

Download Citation:

||https://doi.org/10.6180/jase.2006.9.4.04

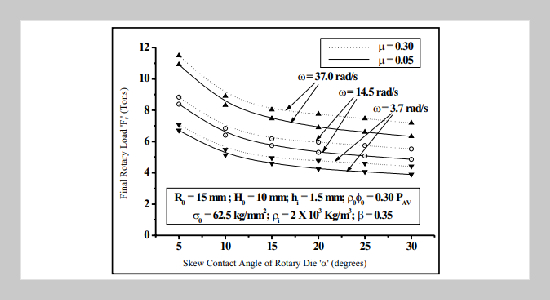

The present paper, which is a continuation to the previous paper, deals with the theoretical and experimental analysis of the rotary phase of the sinter rotary forging. The rotary phase is dealt separately, since mushroom effect during deformation is neglected in the analysis. It is assumed that deformation during sinter rotary forging is an incremental process, in which initially a conical indent surface is created during indentation phase by axial movement of the upper conical die. Subsequently, this deformation is swept throughout the preform surface by angular movement of the upper conical die about its axis. The velocity field, strain rates, internal energy dissipation, frictional energy dissipation and average forging load during rotary phase of the deformation has been formulated in same manner as done in the part I of this paper with indentation phase. The experiments were conducted using aluminium sintered preforms and the results were compared with theoretical ones and were found to be in close agreement. It is assumed that the present work will be a great help in predicting the final rotary forging load and to investigate various deformation characteristics on the design of sinter rotary forging process.ABSTRACT

Keywords:

Sinter Rotary Forging, Conical Die, Rotary Phase, Angular Velocity

REFERENCES