Yin-Tien Wang This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Sung-Lin Wu1 1Mechanical Engineering Department, Tamkang University, Tamsui, Taiwan 251, R.O.C.

Received:

July 28, 2005

Accepted:

October 25, 2005

Publication Date:

June 1, 2006

Download Citation:

||https://doi.org/10.6180/jase.2006.9.2.07

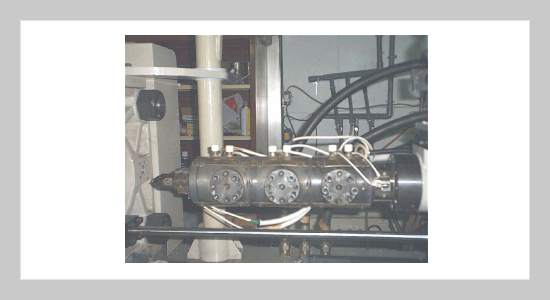

In this paper, a new approach is proposed to model and control the temperature of a thermal barrel of a plastic molding machine. Usually the thermal barrel behavior is expressed in terms of a parameterized linear model to be used in control strategies design. We establish a new model based on the structure of a Takagi-Sugeno fuzzy system, and utilize the clustering method to generate the rule base of the fuzzy system. The proposed methodology is shown to be more effective than a conventional method in constructing system models. Meanwhile, the developed fuzzy model may provide a more accurate output prediction than conventional linear models suggested in the literature. In order to evaluate the control performance, the thermal models are integrated into the Internal Model Controller to control the temperature of a thermal barrel. The system is subjected to a step input and the responses depict the control performance of the models. The fuzzy model shows excellent performance in the step response, while the linear model has an oscillatory output at steady state. The proposed fuzzy model has the capability of application to control temperature in a plastic molding process.ABSTRACT

Keywords:

Fuzzy Systems, Thermal Control, Multivariable Control

REFERENCES