Y. L. Song 1,2, S. C. Tsai1,3 , Y. F. Chou4 , W. J. Chen1 , T. K. Tseng1 , C. S. Tsai1,5 , J. W. Chen2 , Y. D. Yao6 , C. H. Yang7 , M. F. Huang7 and Y. A. Lai7 1Institute for Applied Science & Engineering Research Academia Sinica Taipei, Taiwan 115, R.O.C.

2Department of Physics National Taiwan University Taipei, Taiwan 106, R.O.C.

3Department of Chemical Engineering California State University Long Beach, CA 90840, U.S.A.

4Department of MechanicalEngineering National Taiwan University Taipei, Taiwan 106, R.O.C.

5Department of Electrical Engineering & Computer Science University of California Irvine, CA 92697, U.S.A.

6Insititute of Physics Academia Sinica Taipei, Taiwan 115, R.O.C.

7Department of Mechanical Engineering Chang Gung University Taoyuan, Taiwan 333, R.O.C

Received:

December 29, 2003

Accepted:

January 19, 2004

Publication Date:

June 1, 2004

Download Citation:

||https://doi.org/10.6180/jase.2004.7.2.15

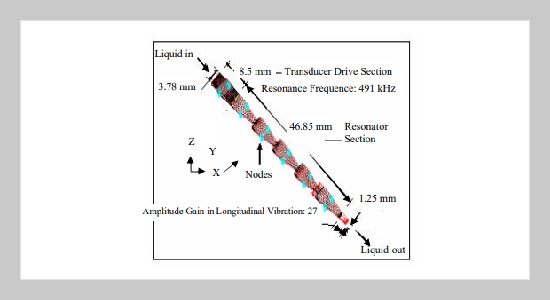

This paper presents the design and characterization of micro-fabricated 0.5 MHz silicon-based ultrasonic nozzle s. Each nozzle is made of a piezoelectric drive section and a silicon-resonator consisting of five Fourier horns, each with half wavelength design and twice amplitude magnification. Results of impedance analysis and measurement of longitudinal vibration confirmed the simulation results with one pure longitudinal vibration mode at the resonant frequency in excellent agreement with the design value. Furthermore, at the resonant frequency, the measured longitudinal vibration amplitude gain at the nozzle tip of the 5-horn nozzle is in good agreement with the theoretical values of 25 . Using this design, very high vibration amplitude gain at the nozzle tip can be achieved with no reduction in the tip cross sectional area for contact of liquid to be atomized. Therefore, the required electric drive power should be drastically reduced, thus avoiding transducer failure in ultrasonic atomization using the 5-horn ultrasonic nozzle.ABSTRACT

Keywords:

Ultrasonic Nozzle, Fourier Horn, High Frequency Nozzle

REFERENCES