Chien-Chung Tsai This email address is being protected from spambots. You need JavaScript enabled to view it.1, Y-Cheng Huang1, Chia-Jung Lee1 and Chia-Ching Chang Chien1 1Department of Optoelectronic System Engineering, Minghsing University of Science and Technology, Hsinchu, Tauwan 304, R.O.C.

Received:

February 23, 2007

Accepted:

March 17, 2007

Publication Date:

June 1, 2007

Download Citation:

||https://doi.org/10.6180/jase.2007.10.2.11

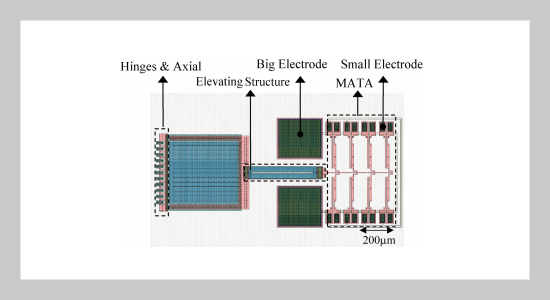

Investigation of surfactant applied on wet etching for releasing the micro optical devices with Micro Array Thermal Actuator, MATA, fabricated by Surface Micromachining common process is proposed in this paper. BOE (buffered oxide etch), concentrated HF (49%), concentrated HF (49%) with 10% surfactant are adopted as the etchants for releasing the micro optical devices in experiment, respectively. Low Temperature Oxide, LTO, is a sacrificial layer material and the etching phenomena will be demonstrated by the three different etchants during the releasing process. The experimental results exhibit Poly-Si is seriously damaged and geometrical dimensions of the micro structure are reduction by BOE (6:1) compared with the original design. On the other hand, the geometrical features of the micro devices are consistency with the original design and successfully released by concentrated HF (49%) etching. However, there are some residual LTO on the surface of Poly 1 layer during the period of concentrated HF (49%) etching process. Nevertheless, the residual LTO on Poly 1 layer surface is significantly improved by the concentrated HF (49%) with 10% surfactant. Finally, the micro optical devices fabricated by SMart common process are successfully released by the concentrated HF (49%) with 10% surfactant and the surfaces of devices are relatively smooth.ABSTRACT

Keywords:

Micro-optics, Surface Micromachining, Wet Etching, Sacrificial Layer

REFERENCES