Dar-Hao Chen This email address is being protected from spambots. You need JavaScript enabled to view it.1 and John Bilyeu1 1Department of Transportation Material and Pavements Section 4203 Bull Creek Road, Austin. TX, U. S. A.

Received:

June 29, 2001

Accepted:

August 5, 2001

Publication Date:

December 1, 2001

Download Citation:

||https://doi.org/10.6180/jase.2001.4.4.05

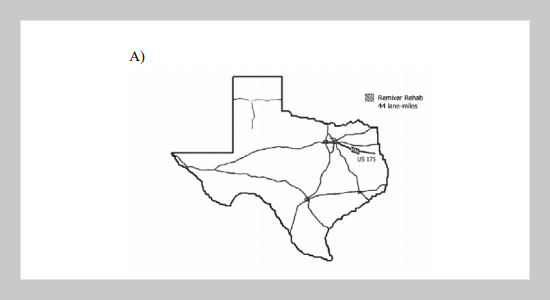

This paper documents the effectiveness of a recycle-in-place (Remixer) process on US175, using results from GPR, FWD, PSPA, condition surveys (crack mapping) and laboratory testing. FWD and PSPA results indicate that the remixed sections are stiff, and the deflection values are in the range typically observed in the Interstate Highway system. This recycling process removes 38mm of AC and adds 25% new material, for a finished thickness of 48mm. The stiffness of the overall pavement structure was not significantly increased by the Remixer process, as the studied pavement sections were already very stiff. Laboratory testing indicated that the Remixer process yields a low penetration number, meaning the material is relatively hard and brittle. Based on the results from FWD, PSPA, and laboratory testing, the pavement structure of the Remixer section possesses sufficient strength to resist rutting. PSPA and Hamburg Wheel-Tracking test results show that the Remixer yields a stiffer material than a conventional overlay. The pavement structure is stiff and should resist rutting. Many reflected cracks have been observed in the Remixer sections. Crack-seal may need to be applied after 1-2 years (or as soon as those cracks open enough to apply crack-seal) to prevent water from entering the pavement layers. The cause for the next major rehabilitation to US175 will mainly be related to reflected cracking. It is concluded that the Remixer treatment with 75% RAP is not a viable treatment in cases where there is a problem with cracking. It is suggested that for US175, the RAP reclaim content should be lowered to approximately 30%, using lower-viscosity asphalt to reduce cracking.ABSTRACT

Keywords:

RAP, Rehabilitation, FWD, SPA, GPR, Hot-in-place Recycle

REFERENCES