D. T. Bergado This email address is being protected from spambots. You need JavaScript enabled to view it.1 and C. Teerawattanasuk1 1School of Civil Engineering Asian Institute of Technology P.O. Box 4, Klong Luang Pathumthani 12120, Thailand

Received:

June 1, 2001

Accepted:

July 9, 2001

Publication Date:

December 1, 2001

Download Citation:

||https://doi.org/10.6180/jase.2001.4.4.02

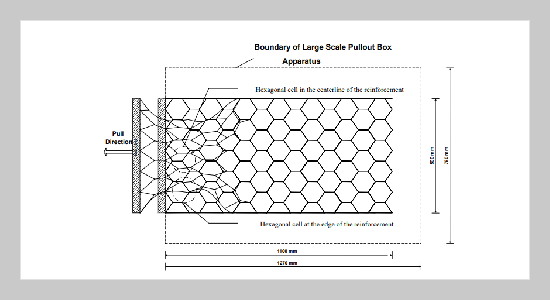

Large pullout tests were conducted on hexagonal wire mesh embedded in silty sand locally known as Ayutthaya sand to investigate the soil reinforcement interaction. PVC-coated of hexagonal wire mesh was tested with different applied normal pressures ranging from 35 to 105 kPa. The hexagonal wire mesh specimens with 80x100 mm cell sizes were pulled at a rate of 1 mm/min. In the conventional pullout test wherein the clamping system is outside the pullout box, the deformation and movement of hexagonal wire mesh known as necking phenomenon occurred simultaneously during the pullout process. In order to reduce this phenomenon, the large pullout test was modified to install the clamping system inside the pullout box hereinafter called “in-soil pullout test”. The total pullout resistance of hexagonal wire mesh reinforcement consists of two components, namely: friction and bearing resistance. An elastic-perfectly plastic model was used to simulate the friction resistance and relative displacement relation of hexagonal wire mesh while a hyperbolic model was applied to simulate the passive bearing resistance of the individual bearing member. The bearing resistance is approximately 4 to 6 times greater than the friction resistance. The maximum pullout resistances increased with increasing specimen lengths as well as the applied normal pressures. The in-soil pullout resistances are about 50% greater than the corresponding results from previous conventional pullout tests. Several analytical models for predicting the pullout resistance of hexagonal wire mesh reinforcement have been proposed and modified in this paper. These proposed analytical models for predicting the pullout resistance and displacement relation agreed with the laboratory test results reasonable well.ABSTRACT

Keywords:

Hexagonal Wire Mesh, Bearing Resistance, Analytical Model, Pullout Box

REFERENCES