P. Pathike This email address is being protected from spambots. You need JavaScript enabled to view it.1, T. Katpradit1, P. Terdtoon1 and P. Sakulchangsatjatai1 1Department of Mechanical Engineering, Faculty of Engineering, Chiang Mai University, Thailand 50200

Received:

November 8, 2012

Accepted:

May 18, 2013

Publication Date:

December 1, 2013

Download Citation:

||https://doi.org/10.6180/jase.2013.16.4.02

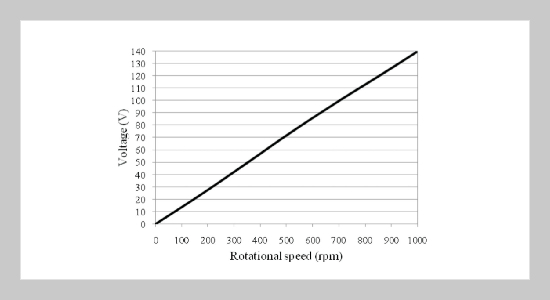

At low wind speed, modern commercial wind turbines have low efficiency for electricity generation. This research hence aims to design a new small wind turbine blade that is suitable for practical applications. Higher torque has to be obtained properly to generate electricity. In order to design and evaluate performance, our mechanical model has been developed based on Blade Element Momentum theory. And, the model is consequently employed to determine the optimized blade shape with the rotor diameter of the wind turbine no higher than 3 m, a design wind velocity of 6 m/s, using 12 V and 24 V battery chargers. The new wind turbine blade has been manually made from fiberglass (GRP) with safety factors of 4 (for 12 V battery) and 2.8 (for 24 V battery). Experimental study is conducted by testing both the commercial blade and our new blade with a specific wind turbine set. It is found that, at designed wind velocity, the efficiency of the novel wind turbine blade of 27% is obtained while that of the commercial wind turbine is only 16%.ABSTRACT

Keywords:

Small Wind Turbine, Low Wind Speed Wind Turbine, Wind Turbine Blade, Blade Shape Design

REFERENCES