Kuo-Liang Jaw1 and Ping-Hsun Chen This email address is being protected from spambots. You need JavaScript enabled to view it.2 1Mosel Vitelic Inc., Taiwan, R.O.C.

2School of Law, Washington University in St. Louis, MO, U.S.A.

Received:

September 1, 2006

Accepted:

May 20, 2008

Publication Date:

September 1, 2008

Download Citation:

||https://doi.org/10.6180/jase.2008.11.3.01

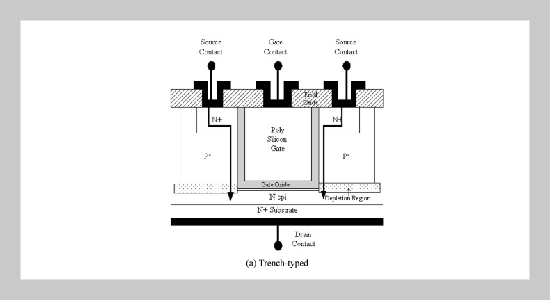

In this article, the pretreatment effects on gate oxide quality of a trench MOSFET device were studied. The process parameters are dry etching after trench patterning, cancellation of sacrificial oxide formation, and inert gas used during gate oxide formation. TEM data were analyzed for gate profiles. Several WAT tests were done for electric verification. It is found that (1) the use of etching machine has a major effect and (2) gate formation in the N2 environment is better at gate oxide quality.ABSTRACT

Keywords:

Power Devices, Gate Oxide, Sacrificial Oxidation, Etching

REFERENCES