Rwei-Ching Chang This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Bo-Chen Huang1 1Department of Mechanical Engineering, St. John’s & St. Mary’s Institute of Technology, Taipei, Taiwan 251, R.O.C.

Received:

January 8, 2005

Accepted:

May 28, 2005

Publication Date:

September 1, 2005

Download Citation:

||https://doi.org/10.6180/jase.2005.8.3.07

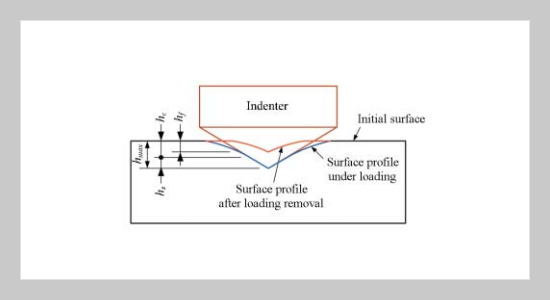

A rapid method to measure the viscoelastic properties of microstructures or nanocomposites is presented in this work. The time-dependent properties of viscoelastic materials in nanoscale are evaluated by using a harmonic nanoindentation test which is performed by a nanoindenter assembled on an atomic force microscope with a three sided pyramidal Berkovich probe tip. The experimental data are calculated by a numerical regression to fit the three-parameter Kelvin-Maxwell viscoelastic model and compared with the data determined from a creep test conducted by a tension machine. It shows that the compliances evaluated from the nanoindentation are smaller than those from the creep test, which means the properties evaluated by the nanoindentation are much stiffer than those by the creep test. Moreover, the relaxation time determined from the nanoindentation is smaller than the one from the creep test, meaning the response in the nanoindentation is quicker than the response in the creep test. The results present the variation of mechanical properties between the macro and micro scales.ABSTRACT

Keywords:

Nanoindentation, Dynamic Response, Viscoelasticity

REFERENCES