Hsiharng Yang 1 and Cheng-Tang Pan2 1Institute of Precision Engineering National Chung Hsing University Taichung, Taiwan 402, R.O.C.

2Mechanical Industry Research Laboratories Industrial Technology Research Institute Hsinchu, Taiwan 310, R.O.C.

Received:

May 16, 2003

Accepted:

June 23, 2003

Publication Date:

September 1, 2003

Download Citation:

||https://doi.org/10.6180/jase.2003.6.3.03

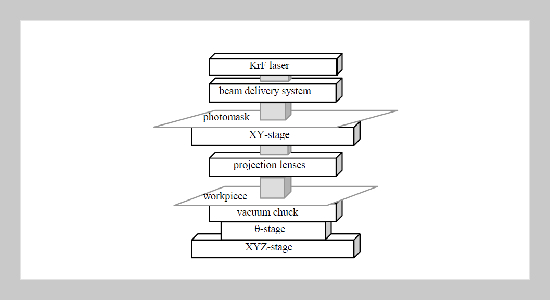

The numerical simulations were used to predict the profile of analogous microstructures following excimer laser ablation to obtain desired micro-optical components. The simulation technique applied in the excimer laser ablation can reduce the quantity of machining experiments. The ablated microstructures with surface roughness of Ra < 20 nm were successfully machined into micro-optical components for further applications. The excimer laser machining parameters included laser energy, shot number, and repetition rate. 3-D microstructures formations were numerically simulated. Various micro-optical components with low aspect ratios can utilize these laser ablation numerical simulations and to form desired application geometries.ABSTRACT

Keywords:

Microlens, Excimer Laser, Micromachining, MEMS

REFERENCES