- [1] P. Yadav, J. Singh, D. K. Srivastava, and V. Mishra. “Environmental pollution and sustainability”. In: En�vironmental sustainability and economy. Elsevier, 2021, 111–120. DOI: 10.1016/B978-0-12-822188-4.00015-4.

- [2] P. O. Ukaogo, U. Ewuzie, and C. V. Onwuka. “Envi�ronmental pollution: causes, effects, and the reme�dies”. In: Microorganisms for sustainable environment and health. Elsevier, 2020, 419–429. DOI: 10.1016/B978-0-12-819001-2.00021-8.

- [3] C. Long, Z. Jiang, J. Shangguan, T. Qing, P. Zhang, and B. Feng, (2021) “Applications of carbon dots in envi�ronmental pollution control: A review" Chemical Engi�neering Journal 406: 126848. DOI: 10.1016/j.cej.2020.126848.

- [4] A. Garcia Ruiz and N. South, (2019) “Surrounded by sound: Noise, rights and environments" Crime, Media, Culture 15(1): 125–141. DOI: 10.1177/1741659017751223.

- [5] Y. Chen, F. Yuan, Q. Su, C. Yu, K. Zhang, P. Luo, D. Hu, and Y. Guo, (2020) “A novel sound absorbing material comprising discarded luffa scraps and polyester fibers" Journal of cleaner production 245: 118917. DOI: 10.1016/j.jclepro.2019.118917.

- [6] C. A. Echeverria, F. Pahlevani, W. Handoko, C. Jiang, C. Doolan, and V. Sahajwalla, (2019) “Engineered hy�brid fibre reinforced composites for sound absorption build�ing applications" Resources, Conservation and Recy�cling 143: 1–14. DOI: 10.1016/j.resconrec.2018.12.014.

- [7] A. Aldalbahi, M. E. El-Naggar, M. H. El-Newehy, M. Rahaman, M. R. Hatshan, and T. A. Khattab, (2021) “Effects of technical textiles and synthetic nanofibers on environmental pollution" Polymers 13(1): 155. DOI: 10.3390/polym13010155.

- [8] F. O. Ajibade, B. Adelodun, K. H. Lasisi, O. O. Fadare, T. F. Ajibade, N. A. Nwogwu, I. D. Sulaymon, A. Y. Ugya, H. C. Wang, and A. Wang. “Environmental pollution and their socioeconomic impacts”. In: Mi�crobe mediated remediation of environmental contami�nants. Elsevier, 2021, 321–354. DOI: 10.1016/B978-0-12-821199-1.00025-0.

- [9] D. Dissanayake, D. Weerasinghe, L. Thebuwanage, and U. Bandara, (2021) “An environmentally friendly sound insulation material from post-industrial textile waste and natural rubber" Journal of Building Engi�neering 33: 101606. DOI: 10.1016/j.jobe.2020.101606.

- [10] S. Gokulkumar, P. Thyla, L. Prabhu, and S. Sathish, (2019) “Measuring methods of acoustic properties and in�fluence of physical parameters on natural fibers: A review" Journal of Natural Fibers: DOI: 10.1080/15440478.2019.1598913.

- [11] J. Sueur, B. Krause, and A. Farina, (2021) “Acoustic biodiversity" Current Biology 31(19): R1172–R1173.

- [12] H. Ryoo and W. Jeon, (2022) “Broadband sound absorp�tion using multiple hybrid resonances of acoustic metasur�faces" International Journal of Mechanical Sciences 229: 107508. DOI: 10.1016/j.ijmecsci.2022.107508.

- [13] N. Gao, Z. Zhang, J. Deng, X. Guo, B. Cheng, and H. Hou, (2022) “Acoustic metamaterials for noise re�duction: a review" Advanced Materials Technologies 7(6): 2100698. DOI: 10.1002/admt.202100698.

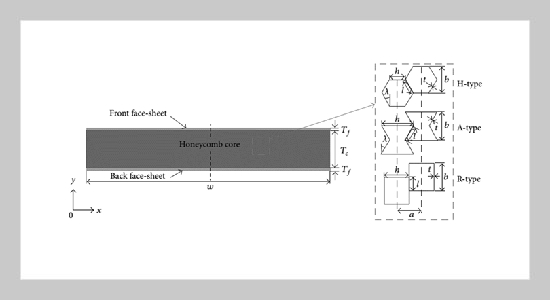

- [14] C. Dong, Z. Liu, R. Pierce, X. Liu, and X. Yi, (2023) “Sound absorption performance of a micro perforated sand�wich panel with honeycomb-hierarchical pore structure core" Applied Acoustics 203: 109200. DOI: 10.1016/j.apacoust.2022.109200.

- [15] W. He, X. Peng, F. Xin, and T. J. Lu, (2022) “Ultralight micro-perforated sandwich panel with hierarchical honey�comb core for sound absorption" Journal of Sandwich Structures & Materials 24(1): 201–217. DOI: 10.1177/1099636221993880.

- [16] J. Pierre, F. Iervolino, R. D. Farahani, N. Piccirelli, M. Lévesque, and D. Therriault, (2023) “Material ex�trusion additive manufacturing of multifunctional sand�wich panels with load-bearing and acoustic capabilities for aerospace applications" Additive Manufacturing 61: 103344. DOI: 10.1016/j.addma.2022.103344.

- [17] L. Kang, C. Sun, F. An, and B. Liu, (2022) “A bending stiffness criterion for sandwich panels with high sound insulation and its realization through low specific modulus layers" Journal of Sound and Vibration 536: 117149. DOI: 10.1016/j.jsv.2022.117149.

- [18] L. Kang, B. Liu, F. An, and D. Wei, (2022) “Mechanical and vibro-acoustic performance of sandwich panel with perforated honeycomb cores" The Journal of the Acous�tical Society of America 152(3): 1539–1546. DOI: 10.1121/10.0013997.

- [19] G. Di Bella and G. Palomba, (2023) “Cork/aluminium double-layer sandwich panels under impact loading for lightweight ship structures" International journal of crashworthiness 28(6): 797–808. DOI: 10.1080/13588265.2022.2130619.

- [20] Y. Jin, Y. Yang, Z. Wen, L. He, Y. Cang, B. Yang, B. Djafari-Rouhani, Y. Li, and Y. Li, (2022) “Lightweight sound-absorbing metastructures with perforated fish-belly panels" International Journal of Mechanical Sci�ences 226: 107396. DOI: 10.1016/j.ijmecsci.2022.107396.

- [21] M. Ghafouri, M. Ghassabi, M. R. Zarastvand, and R. Talebitooti, (2022) “Sound propagation of three-dimensional sandwich panels: Influence of three�dimensional re-entrant auxetic core" AIAA Journal 60(11): 6374–6384. DOI: 10.2514/1.J061219.

- [22] G. D. Goh, S. J. C. Neo, V. Dikshit, and W. Y. Yeong, (2022) “Quasi-static indentation and sound-absorbing properties of 3D printed sandwich core panels" Journal of Sandwich Structures & Materials 24(2): 1206–1225. DOI: 10.1177/10996362211037015.

- [23] A. Namvar and A. Vosoughi, (2020) “Design optimiza�tion of moderately thick hexagonal honeycomb sandwich plate with modified multi-objective particle swarm opti�mization by genetic algorithm (MOPSOGA)" Compos�ite Structures 252: 112626. DOI: 10.1016/j.compstruct.2020.112626.

- [24] D.-L. Peng, P. Hu, and B.-L. Zhu, (2008) “The modified method of measuring the complex transmission coefficient of multilayer acoustical panel in impedance tube" Ap�plied acoustics 69(12): 1240–1248. DOI: 10.1016/j.apacoust.2007.10.002.

- [25] K. M. Ho, Z. Yang, X. Zhang, and P. Sheng, (2005) “Measurements of sound transmission through panels of locally resonant materials between impedance tubes" Applied acoustics 66(7): 751–765. DOI: 10.1016/j.apacoust.2004.11.005.

- [26] D. Wang, S. Xie, Z. Feng, X. Liu, and Y. Li, (2020) “Investigating the effect of dimension parameters on sound transmission losses in Nomex honeycomb sand�wich" Applied Sciences 10(9): 3109. DOI: 10.3390/app10093109.

- [27] G. Serhat. “Comparison of vibro-acoustic perfor�mance metrics in the design and optimization of stiff�ened composite fuselages”. In: INTER-NOISE and NOISE-CON Congress and Conference Proceedings. 253. 2. Institute of Noise Control Engineering. 2016, 6163–6174.

- [28] T. Liu, X. Gao, and Q. Yuan, (2017) “An improved gradient-based NSGA-II algorithm by a new chaotic map model" Soft Computing 21: 7235–7249. DOI: 10.1007/s00500-016-2268-x.

- [29] R. Galgalikar and L. L. Thompson, (2016) “Design optimization of honeycomb core sandwich panels for max�imum sound transmission loss" Journal of Vibration and Acoustics 138(5): 051005. DOI: 10.1115/1.4033459.