REFERENCES

- [1] M. Zeynalian, A. H. Hajialirezaei, A. R. Razmi, and M. Torabi, (2020) “Carbon dioxide capture from compressed air energy storage system" Applied Thermal Engineering 178: 115593. DOI: 10.1016/j.applthermaleng.2020.115593.

- [2] T. Zurrer, K. Wong, J. Horlyck, E. C. Lovell, J. Wright, N. M. Bedford, Z. Han, K. Liang, J. Scott, and R. Amal, (2021) “Mixed-Metal MOF-74 Templated Catalysts for Efficient Carbon Dioxide Capture and Methanation" Advanced Functional Materials 31(9): 2007624. DOI: 10.1002/adfm.202007624.

- [3] P. Chaiwang, C. Sakaunnapaporn, T. Sema, P. Piumsomboon, B. Chalermsinsuwan, et al., (2020) “Statistical experimental design for carbon dioxide capture in circulating fluidized bed using computational fluid dynamics simulation: effect of operating parameters" Journal of Applied Science and Engineering 23(2): 303–317. DOI: 10.6180/JASE.202006_23(2).0014.

- [4] M. Imran, U. Ali, and A. Hasnain, (2021) “Impact of blends of aqueous amines on absorber intercooling for post combustion CO2 capture system" Energy & Environment 32(5): 921–944. DOI: 10.1177/0958305X20982835.

- [5] V. Buvik, S. J. Vevelstad, O. G. Brakstad, and H. K. Knuutila, (2021) “Stability of Structurally Varied Aqueous Amines for CO2 Capture" Industrial & Engineering Chemistry Research 60(15): 5627–5638. DOI: 10.1021/ACS.IECR.1C00502.

- [6] F. Barzagli, C. Giorgi, F. Mani, and M. Peruzzini, (2019) “Comparative study of CO2 capture by aqueous and nonaqueous 2-amino-2-methyl-1-propanol based absorbents carried out by 13C NMR and enthalpy analysis" Industrial & Engineering Chemistry Research 58(11): 4364–4373. DOI: 10.1021/ACS.IECR.9B00552.

- [7] X. E. Hu, L. Liu, X. Luo, G. Xiao, E. Shiko, R. Zhang, X. Fan, Y. Zhou, Y. Liu, Z. Zeng, et al., (2020) “A review of N-functionalized solid adsorbents for post-combustion CO2 capture" Applied Energy 260: 114244. DOI: 10.1016/j.apenergy.2019.114244.

- [8] I. O. Furtado, T. C. dos Santos, L. F. Vasconcelos, L. T. Costa, R. G. Fiorot, C. M. Ronconi, and J. W. d. M. Carneiro, (2021) “Combined theoretical and experimental studies on CO2 capture by amine-activated glycerol" Chemical Engineering Journal 408: 128002. DOI: 10.1016/j.cej.2020.128002.

- [9] M. Pardakhti, T. Jafari, Z. Tobin, B. Dutta, E. Moharreri, N. S. Shemshaki, S. Suib, and R. Srivastava, (2019) “Trends in solid adsorbent materials development for CO2 capture" ACS applied materials & interfaces 11(38): 34533–34559. DOI: 10.1021/acsami.9b08487.

- [10] I. Sharma, D. Friedrich, T. Golden, and S. Brandani, (2020) “Monolithic adsorbent-based rapid-cycle vacuum pressure swing adsorption process for carbon capture from small-scale steam methane reforming" Industrial & Engineering Chemistry Research 59(15): 7109–7120. DOI: 10.1021/acs.iecr.9b05337.

- [11] N. Q. Long and T. X. Loc, (2016) “Experimental and modeling study on room-temperature removal of hydrogen sulfide using a low-cost extruded Fe2O3-based adsorbent" Adsorption 22(3): 397–408. DOI: 10.1007/s10450-016-9790-0.

- [12] C. Feng, E. Jiaqiang, W. Han, Y. Deng, B. Zhang, X. Zhao, and D. Han, (2021) “Key technology and application analysis of zeolite adsorption for energy storage and heat-mass transfer process: A review" Renewable and Sustainable Energy Reviews 144: 110954. DOI:10.1016/J.RSER.2021.110954.

- [13] R. Yu et al., (2020) “Comparative study on the preparation of Co/HZSM-5 molecular sieves by ion exchange method and impregnation method" Journal of Applied Science and Engineering 23(4): 695–699. DOI: 10.6180/JASE.202012_23(4).0014.

- [14] M. Plaza, S. Garcia, F. Rubiera, J. Pis, and C. Pevida, (2010) “Post-combustion CO2 capture with a commercial activated carbon: comparison of different regeneration strategies" Chemical Engineering Journal 163(1-2): 41–47. DOI: 10.1016/J.CEJ.2010.07.030.

- [15] G. Zhan, L. Bai, S. Zeng, Y. Bai, H. Su, B.Wu, F. Cao, D. Shang, Z. Li, X. Zhang, et al., (2020) “Dynamic Process Simulation and Assessment of CO2 Removal from Confined Spaces Using Pressure Swing Adsorption" Industrial & Engineering Chemistry Research 59(37): 16407–16419. DOI: 10.1021/acs.iecr.0c02255.

- [16] X. Qian, G. Bai, P. He, Z. Fei, Q. Liu, Z. Zhang, X. Chen, J. Tang, M. Cui, and X. Qiao, (2018) “Rapid CO2 adsorption over hierarchical ZSM-5 with controlled mesoporosity" Industrial & Engineering Chemistry Research 57(49): 16875–16883. DOI: 10.1021/ACS.IECR.8B03325.

- [17] A. A. Dabbawala, I. Ismail, B. V. Vaithilingam, K. Polychronopoulou, G. Singaravel, S. Morin, M. Berthod, and Y. AlWahedi, (2020) “Synthesis of hierarchical porous Zeolite-Y for enhanced CO2 capture" Microporous and Mesoporous Materials 303: 110261. DOI: 10.1016/j.micromeso.2020.110261.

- [18] H. Qu, Y. Ma, B. Li, and L. Wang, (2020) “Hierarchical zeolites: synthesis, structural control, and catalytic applications" Emergent Materials 3(3): 225–245. DOI: 10.1007/s42247-020-00088-z.

- [19] S. Ullah, M. A. Bustam, A. G. Al-Sehemi, M. A. Assiri, F. A. A. Kareem, A. Mukhtar, M. Ayoub, and G. Gonfa, (2020) “Influence of post-synthetic graphene oxide (GO) functionalization on the selective CO2/CH4 adsorption behavior of MOF-200 at different temperatures; anexperimental and adsorption isotherms study" Microporous and Mesoporous Materials 296: 110002. DOI: 10.1016/j.micromeso.2020.110002.

- [20] X. Du, W. Guang, Y. Cheng, Z. Hou, Z. Liu, H. Yin, L. Huo, R. Lei, and C. Shu, (2020) “Thermodynamics analysis of the adsorption of CH4 and CO2 on montmorillonite" Applied Clay Science 192: 105631. DOI:10.1016/j.clay.2020.105631.

- [21] J. Bujdak, (2020) “Adsorption kinetics models in clay systems. The critical analysis of pseudo-second order mechanism" Applied Clay Science 191: 105630. DOI: 10.1016/j.clay.2020.105630.

- [22] N. Q. Long, H. T. Vuong, H. K. P. Ha,W. Kuniawan, H. Hinode, and T. Baba, (2016) “Preparation, characterization and H2S adsorptive removal of ion-exchanged zeolite X" ASEAN Engineering Journal 5(1): 4–14.

- [23] L. Li, Y. Duan, S. Liao, Q. Ke, Z. Qiao, and Y. Wei, (2020) “Adsorption and separation of propane/propylene on various ZIF-8 polymorphs: Insights from GCMC simulations and the ideal adsorbed solution theory (IAST)" Chemical Engineering Journal 386: 123945. DOI: 10.1016/j.cej.2019.123945.

- [24] L. S. M. Nazir, Y. F. Yeong, and T. L. Chew, (2020) “Controlled growth of Faujasite zeolite with NaX topology by manipulating solution aging and Na2O/Al2O3 ratios" Colloids and Surfaces A: Physicochemical and Engineering Aspects 600: 124803. DOI: 10.1016/j.colsurfa.2020.124803.

- [25] R. Zhang, P. Zhong, H. Arandiyan, Y. Guan, J. Liu, N. Wang, Y. Jiao, and X. Fan, (2020) “Using ultrasound to improve the sequential post-synthesis modification method for making mesoporous Y zeolites" Frontiers of Chemical Science and Engineering 14(2): 275–287. DOI: 10.1007/s11705-019-1905-1.

- [26] M. Thommes, K. Kaneko, A. V. Neimark, J. P. Olivier, F. Rodriguez-Reinoso, J. Rouquerol, and K. S. Sing, (2015) “Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report)" Pure and applied chemistry 87(9-10): 1051–1069. DOI: 10.1515/PAC-2014-1117.

- [27] X. Du, Y. Cheng, Z. Liu, H. Yin, T.Wu, L. Huo, and C. Shu, (2021) “CO2 and CH4 adsorption on different rank coals: A thermodynamics study of surface potential, Gibbs free energy change and entropy loss" Fuel 283: 118886. DOI: 10.1016/j.fuel.2020.118886.

- [28] J. H. Lee and D. H. Suh, (2021) “Entropy, enthalpy, and Gibbs free energy variations of 133Cs via CO2-activated carbon filter and ferric ferrocyanide hybrid composites" Nuclear Engineering and Technology 53(11): 3711–3716. DOI: 10.1016/J.NET.2021.06.006.

- [29] A. Kiselev, (1961) “Surface chemistry, adsorption energy, and adsorption equilibria" Quarterly Reviews, Chemical Society 15(1): 99–124. DOI: 10.1039/QR9611500099.

- [30] V. Garshasbi, M. Jahangiri, and M. Anbia, (2017) “Equilibrium CO2 adsorption on zeolite 13X prepared from natural clays" Applied Surface Science 393: 225–233. DOI: 10.1016/J.APSUSC.2016.09.161.

- [31] X. Du, W. Guang, Y. Cheng, Z. Hou, Z. Liu, H. Yin, L. Huo, R. Lei, and C. Shu, (2020) “Thermodynamics analysis of the adsorption of CH4 and CO2 on montmorillonite" Applied Clay Science 192: 105631. DOI:10.1016/j.clay.2020.105631.

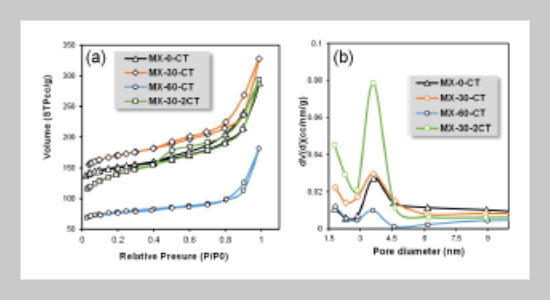

- [32] H. G. H. Tran, T. T. P. Nguyen, T. L. Bui, C. V. Dang, N. Q. T. Le, T. G. H. Nguyen, T. A. Ngo, Q. L. Nguyen, et al., (2021) “Mesostructured Zeolites Prepared by One-Pot Top-Down Synthesis Route for Carbon Dioxide Adsorption" Chemical Engineering Transactions 83: 67–72. DOI: 10.3303/CET2183012.

- [33] Y. Xiao, G. He, and M. Yuan, (2018) “Adsorption equilibrium and kinetics of methanol vapor on zeolites NaX, KA, and CaA and activated alumina" Industrial & Engineering Chemistry Research 57(42): 14254–14260. DOI: 10.1021/ACS.IECR.8B04076.