Jin-Yih Kao1, Sheng-Yao Lin This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Yih-Sharng Chen2 1Department of Mechanical Engineering, Lunghwa University of Science and Technology, Taoyuan, Taiwan 333, R.O.C.

2Department of Cardiovascular Surgery, National Taiwan University Hospital, Taipei, Taiwan 100, R.O.C.

Received:

October 25, 2017

Accepted:

February 7, 2018

Publication Date:

September 1, 2018

Download Citation:

||https://doi.org/10.6180/jase.201809_21(3).0005

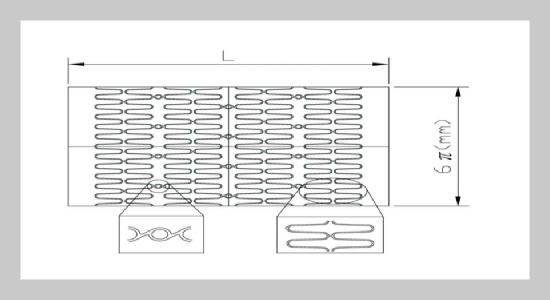

The process of surface finishing is crucial to the performance of stents. This study explored the surface finishing of 316LVM stainless steel stents produced by laser cutting. Our results from measuring the quantity of material removed through these cleaning processes demonstrate that the slag formed on the surface of stents can be removed by means of acid pickling and electrolytic polishing. The stent surface process of stent after achieved a 78% improvement in surface roughness with an acceptable weight loss of 16.7% and a width reduction of 5.95%. In addition, the cleaning processes, as applied in the present study, resulted in the removal of appropriate quantities of stent material, resulting in devices with a superior finish as well as mechanical integrity. It is hoped that these results can contribute to the integrity and accuracy of associated studies in the future, including research preceding clinical animal testing and human trials and protection of patients during implantation procedures.ABSTRACT

Keywords:

Stent, Surface Finishing, Acid Pickling, Electrolytic Polishing

REFERENCES