Hong Zhang1,2,3, Yijing Feng4 , Zhengxin Xiang1,2 and Ding Feng This email address is being protected from spambots. You need JavaScript enabled to view it.1,2 1Hubei Engineering Research Center of Oil and Gas Drilling and Completion Tools, Yangtze University, Jingzhou, Hubei 434023, P.R. China

2Hubei Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University, Wuhan, Hubei 430100, P.R. China

3Hubei Key Laboratory of Hydroelectric Machinery Design & Maintenance, China Three Gorges University, Yichang, Hubei 443002, P.R. China

4School of Mechanical and Transportation Engineering, China University of Petroleum, Beijing 102249, P.R. China

Received:

December 27, 2016

Accepted:

April 13, 2017

Publication Date:

December 1, 2017

Download Citation:

||https://doi.org/10.6180/jase.2017.20.4.04

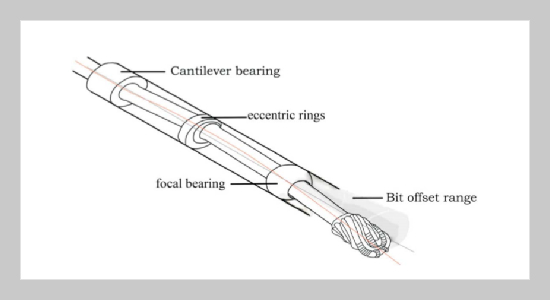

The build-up rate and steering force of the wellbore trajectory control tool has a close relationship with its shaft deformation, which mainly depends on the eccentric movement of the shaft and its flexural deformation. In combination with the working principle of the shaft of the tool, the deformation motion of the shaft was analyzed first, based on which, the flexural equation of the shaft at the static bias state was deduced as well as its angle equations, bearing reaction equations and bending moment equations. According to the deduced equations, the mechanical model of the shaft was established and optimized. To test and verify the reliability and feasibility of the model, the lab simulation experiment was carried out by using the dynamic simulation test bench of the wellbore trajectory control tool, and the bit deflection angle was acquired. A comparison was made between the data from the model and the one from the experiments. The results show that the data measured in experiments is very close to the data derived from the theoretical equations, thus verifying the feasibility of the established mechanical model of the shaft, which provides reference for the shaft design of the wellbore trajectory control tool.ABSTRACT

Keywords:

Deformation Movement, Mechanical Model, Lab Testing, Wellbore Trajectory Control Tool, Shaft, Bias Units

REFERENCES