Chien-Ting Wu This email address is being protected from spambots. You need JavaScript enabled to view it.1, Chun-Sung Chen2 and Ming-Wei Chang3 1Department of Civil Engineering, National Chiao Tung University, Hsinchu 300, Taiwan, R.O.C.

2Department of Geomatics, Chien Hsin University of Science and Technology, Zhongli City, Taoyuan County 320, Taiwan, R.O.C.

3National Measurement Laboratory, Industrial Technology Research Institute, Taiwan, R.O.C

Received:

August 20, 2012

Accepted:

November 28, 2012

Publication Date:

March 1, 2013

Download Citation:

||https://doi.org/10.6180/jase.2013.16.1.10

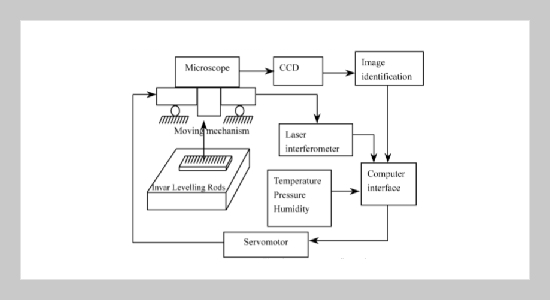

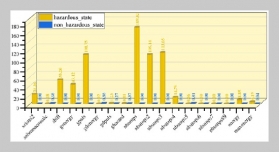

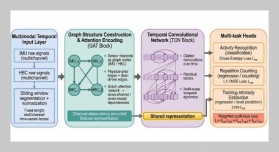

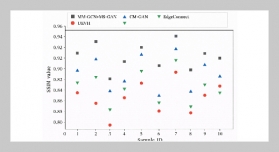

Bar code line and barcode invar leveling staffs must be calibrated for precise leveling. According to first-order leveling specifications instituted by the Ministry of Internal Affairs, the fixed standard for rod calibration uncertainties is ≤ 50 μm. At the National Measurement Laboratory (NML), no equipment meets this requirement. The purpose of this study of the existing calibration system at the National Measurement Laboratory is to reduce the calibration uncertainties to an allowable level. An automated calibration system for invar leveling staffs was established in this study, and the uncertainty of the calibration data was evaluated. The National Measurement Laboratory, supervised by the Development Center for Measuring Technology of the Industrial Technology Research Institute, employs a stabilized-frequency laser interferometer, a charge-coupled device (CCD) microscopic monitor and a precise movement mechanism for the calibration of invar leveling staffs. As part of the process, the error factors and the amount of uncertainty associated with line scale and barcode leveling staffs are assessed. At the 95% confidence level, the expanded uncertainties of the graduations were 22 μm and 21 μm for line scale and bar coded staffs, respectively, which meet user requirements.ABSTRACT

Keywords:

Invar Leveling Staffs, Calibration System, Estimate of Uncertainty, Measuring Technology

REFERENCES