Rome-Ming Wu This email address is being protected from spambots. You need JavaScript enabled to view it.1, Tsung-Hao Lee1 and Wen-Jie Yang1 1Department of Chemical and Materials Engineering, Tamkang University, Tamsui, Taiwan 251, R.O.C.

Received:

May 1, 2006

Accepted:

June 7, 2006

Publication Date:

December 1, 2007

Download Citation:

||https://doi.org/10.6180/jase.2007.10.4.03

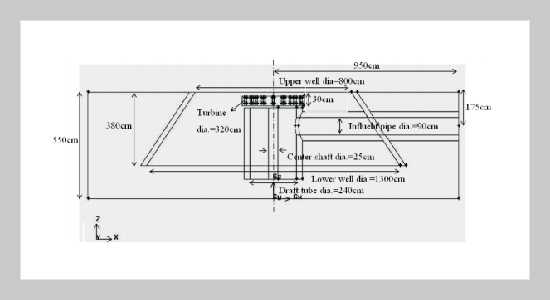

In this work the geometry of the sludge blanket clarifier was established based on Bansin Water Treatment Plant, Taiwan. The meshes of the clarifier were constructed, and the boundary conditions were set, then the velocity field of the clarifier was calculated. Two models were computed individually: 1. the fluid in the whole clarifier is pure water - a test for obtaining the flow pattern; 2. the flow field contains a homogeneous blanket of permeability k and pure water - a test modeling the sludge blanket as a homogeneous porous medium. The results showed that when the inlet velocity decreased from νx = 0.3 m/s to 0.1 m/s, the effect of channel flow or break-through of blanket decreased. Decreasing of the rotation velocity of the impeller could decrease the effect of the reversed flow in the secondary reactor. In the case of a uniform blanket on the bottom of the clarifier, the high permeability of the blanket indicates the similar velocity field with those of pure water. While the clarifier with a low permeability blanket, the rebound of the blanket becomes seriously.ABSTRACT

Keywords:

Clarifier, 3D Simulation, Sludge, Blanket, Water Treatment

REFERENCES