REFERENCES

- [1] P. Phanthong, P. Reubroycharoen, X. Hao, G. Xu, A. Abudula, and G. Guan, (2018) “Nanocellulose: Extraction and application" Carbon Resources Conversion 1(1): 32–43. DOI: 10.1016/j.crcon.2018.05.004.

- [2] K. Karimi, M. Shafiei, and R. Kumar. Progress in physical and chemical pretreatment of lignocellulosic biomass. 9783642345197. Cited by: 113. 2013, 53–96. DOI: 10.1007/978-3-642-34519-7_3.

- [3] W. Braide, I. Kanu, U. Oranusi, and S. Adeleye, (2016) “Production of bioethanol from agricultural waste" Journal of Fundamental and Applied Sciences 8(2): 372–386.

- [4] B. Ebrahimi, R. Mohammadi, M. Rouhi, A. M. Mortazavian, S. Shojaee-Aliabadi, and M. R. Koushki, (2018) “Survival of probiotic bacteria in carboxymethyl cellulose-based edible film and assessment of quality parameters" LWT 87: 54–60. DOI: 10.1016/j.lwt.2017.08.066.

- [5] I. T. Seoane, L. B. Manfredi, and V. P. Cyras, (2015) “Properties and processing relationship of polyhydroxybutyrate and cellulose biocomposites" Procedia Materials Science 8: 807–813.

- [6] A. K. Veeramachineni, T. Sathasivam, S. Muniyandy, P. Janarthanan, S. J. Langford, and L. Y. Yan, (2016) “Optimizing extraction of cellulose and synthesizing pharmaceutical grade carboxymethyl sago cellulose from Malaysian sago pulp" Applied Sciences (Switzerland) 6(6): DOI: 10.3390/app6060170.

- [7] P. Rachamontree, T. Douzou, K. Cheenkachorn, M. Sriariyanun, and K. Rattanaporn, (2020) “Furfural: A sustainable platform chemical and fuel" Applied Science and Engineering Progress 13(1): 3–10. DOI: 10.14416/j.asep.2020.01.003.

- [8] Y.-S. Cheng, P. Mutrakulcharoen, S. Chuetor, K. Cheenkachorn, P. Tantayotai, E. J. Panakkal, and M. Sriariyanun, (2020) “Recent situation and progress in biorefining process of lignocellulosic biomass: Toward green economy" Applied Science and Engineering Progress 13(4): DOI: 10.14416/J.ASEP.2020.08.002.

- [9] W. Fatriasari,W. Syafii, N. J.Wistara, K. Syamsu, and B. Prasetya, (2014) “The characteristic changes of betung bamboo (Dendrocalamus asper) pretreated by fungal pretreatment" International Journal of Renewable Energy Development 3(2): 133–143. DOI: 10.14710/ijred.3.2.133-143.

- [10] S. Harun and S. K. Geok, (2016) “Effect of sodium hydroxide pretreatment on rice straw composition" Indian Journal of Science and Technology 9(21): DOI: 10.17485/ijst/2016/v9i21/95245.

- [11] R. Maryana, T. Jatmiko, D. Prasetyo, W. Rizal, A. Suwanto, A. Praharasti, A. Indrianingsih, M. Anwar, and A. Rizaluddin. “Evaluation of high purity cellulose production from pretreated various agricultural biomass wastes”. In: 251. 1. Cited by: 5; All Open Access, Bronze Open Access. 2019. DOI: 10.1088/1755-1315/251/1/012001.

- [12] S. Mourtzinis, K. B. Cantrell, F. J. Arriaga, K. S. Balkcom, J. M. Novak, J. R. Frederick, and D. L. Karlen, (2014) “Distribution of Structural Carbohydrates in Corn Plants Across the Southeastern USA" Bioenergy Research 7(2): 551–558. DOI: 10.1007/s12155-014-9429-5.

- [13] A. A. Oun and J.-W. Rhim, (2016) “Isolation of cellulose nanocrystals from grain straws and their use for the preparation of carboxymethyl cellulose-based nanocomposite films" Carbohydrate Polymers 150: 187–200. DOI: 10.1016/j.carbpol.2016.05.020.

- [14] GAPKI. Kinerja Industri Sawit Indonesia 2019. http://gapki.id/kinerja_industri_sawit_indonesia_2019.pdf. Jakarta. 2020.

- [15] Susilawati and Supijatno, (2015) “Waste management of palm oil (Elaeis guineensis Jacq.) in oil palm plantation riau" Buletin Agrohorti 3(2): 203–212.

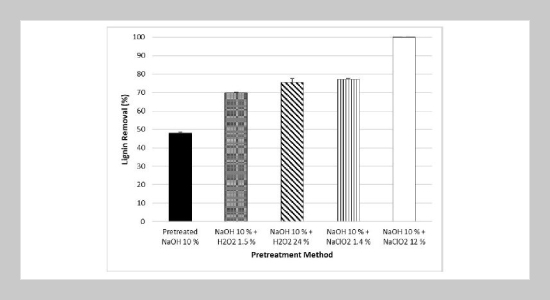

- [16] V. Barlianti, D. Dahnum, H. Hendarsyah, and H. Abimanyu, (2015) “Effect of alkaline pretreatment on properties of lignocellulosic oil palm waste" Procedia Chemistry 16: 195–201.

- [17] Z. Wang, Z. Yao, J. Zhou, and Y. Zhang, (2017) “Reuse of waste cotton cloth for the extraction of cellulose nanocrystals" Carbohydrate Polymers 157: 945–952. DOI: 10.1016/j.carbpol.2016.10.044.

- [18] H. Zhang, Y. Chen, S. Wang, L. Ma, Y. Yu, H. Dai, and Y. Zhang, (2020) “Extraction and comparison of cellulose nanocrystals from lemon (Citrus limon) seeds using sulfuric acid hydrolysis and oxidation methods" Carbohydrate Polymers 238: DOI: 10.1016/j.carbpol.2020.116180.

- [19] S. A, B. D, and S. S, (2018) “Pengaruh Proses Pemutihan Multi Tahap Serat Selulosa Dari Limbah Tandan Kosong Kelapa Sawit" Jurnal kimia dan kemasan 40(2): 71–78.

- [20] K. C. C. d. C. Benini, H. J. C. Voorwald, M. O. H. Cioffi, M. C. Rezende, and V. Arantes, (2018) “Preparation of nanocellulose from Imperata brasiliensis grass using Taguchi method" Carbohydrate Polymers 192: 337–346. DOI: 10.1016/j.carbpol.2018.03.055.

- [21] A. Y. Meliko˘ glu, S. E. Bilek, and S. Cesur, (2019) “Optimum alkaline treatment parameters for the extraction of cellulose and production of cellulose nanocrystals from apple pomace" Carbohydrate Polymers 215: 330–337. DOI: 10.1016/j.carbpol.2019.03.103.

- [22] E. N. N. Arbaain, E. K. Bahrin, M. F. Ibrahim, Y. Ando, and S. Abd-Aziz, (2019) “Biological pretreatment of oil palm empty fruit bunch by Schizophyllum commune ENN1 without washing and nutrient addition" Processes 7(7): DOI: 10.3390/pr7070402.

- [23] Isroi, M. M. Ishola, R. Millati, S. Syamsiah, M. N. Cahyanto, C. Niklasson, and M. J. Taherzadeh, (2012) “Structural changes of oil palm empty fruit bunch (OPEFB) after fungal and phosphoric acid pretreatment" Molecules 17(12): 14995–15012. DOI: 10.3390/molecules171214995.

- [24] M. Muryanto, Y. Sudiyani, and H. Abimanyu, (2016) “Optimasi proses perlakuan awal NaOH tandan kosong kelapa sawit untuk menjadi bioetanol" Jurnal Kimia Terapan Indonesia 18(01): 27–35.

- [25] N. N. Solihat, F. P. Sari, L. Risanto, S. H. Anita, Fitria, W. Fatriasari, and E. Hermiati, (2017) “Disruption of oil palm empty fruit bunches by microwave-assisted oxalic acid pretreatment" Journal of Mathematical and Fundamental Sciences 49(3): 244–257. DOI: 10.5614/j.math.fund.sci.2017.49.3.3.

- [26] D. Jose, N. Kitiborwornkul, M. Sriariyanun, and K. Keerthi, (2022) “A Review on Chemical Pretreatment Methods of Lignocellulosic Biomass: Recent Advances and Progress" Applied Science and Engineering Progress 15(4): 6210–6210.

- [27] Z. Song, G. Yang, X. Liu, Z. Yan, Y. Yuan, and Y. Liao, (2014) “Comparison of seven chemical pretreatments of corn straw for improving methane yield by anaerobic digestion" PLoS ONE 9(4): DOI: 10.1371/journal.pone.0093801.

- [28] B. Xiao, X. Sun, and R. Sun, (2001) “Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw" Polymer Degradation and Stability 74(2): 307–319. DOI: 10.1016/S0141-3910(01)00163-X.

- [29] J. Gominho, R. Costa, A. Lourenço, D. Neiva, and H. Pereira, (2019) “The effect of different pre-treatments to improve delignification of eucalypt stumps in a biorefinery context" Bioresource Technology Reports 6: 89–95. DOI: 10.1016/j.biteb.2019.02.004.

- [30] P. Rodsamran and R. Sothornvit, (2015) “Renewable cellulose source: Isolation and characterisation of cellulose from rice stubble residues" International Journal of Food Science and Technology 50(9): 1953–1959. DOI: 10.1111/ijfs.12862.

- [31] A. Goshadrou, K. Karimi, and M. J. Taherzadeh, (2011) “Bioethanol production from sweet sorghum bagasse by Mucor hiemalis" Industrial Crops and Products 34(1): 1219–1225. DOI: 10.1016/j.indcrop.2011.04.018.

- [32] P. Penjumras, R. B. A. Rahman, R. A. Talib, and K. Abdan, (2014) “Extraction and characterization of cellulose from durian rind" Agriculture and Agricultural Science Procedia 2: 237–243.

- [33] N. Johar, I. Ahmad, and A. Dufresne, (2012) “Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk" Industrial Crops and Products 37(1): 93–99. DOI: 10.1016/j.indcrop.2011.12.016.

- [34] J. Lamaming, R. Hashim, O. Sulaiman, C. P. Leh, T. Sugimoto, and N. A. Nordin, (2015) “Cellulose nanocrystals isolated from oil palm trunk" Carbohydrate Polymers 127: 202–208. DOI: 10.1016/j.carbpol.2015.03.043.

- [35] N. Ngadi and N. S. Lani, (2014) “Extraction and characterization of cellulose from empty fruit bunch (EFB) fiber" Jurnal Teknologi (Sciences and Engineering) 68(5): 35–39. DOI: 10.11113/jt.v68.3028.