Chun-Sheng Wang1 , Ying-Ying Wang This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Qiu-Ying Du2 1School of Petroleum Engineering, Northeast Petroleum University, Daqing 163318, Heilongjiang Province, P.R. China

2School of Petroleum Engineering, China University of Petroleum, Qingdao 266580, Shandong Province, P.R. China

Received:

February 20, 2017

Accepted:

July 3, 2017

Publication Date:

September 1, 2017

Download Citation:

||https://doi.org/10.6180/jase.2017.20.3.04

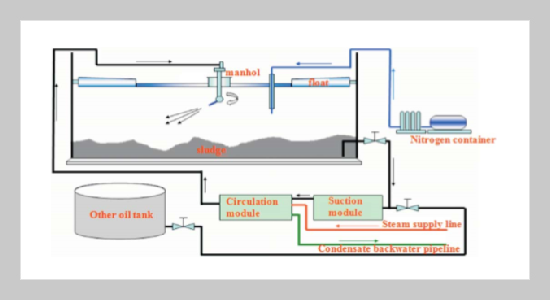

During long time storage of oil, there will be oil contamination hanging in the oil tank wall and bottom, the oil contamination will not only occupy the capacity of the storage tanks, but also affect the inspection and maintenance of the storage tank. Therefore, it is necessary to clean the tank regularly. Mechanical tank cleaning has high efficiency, more secure, more environmental protection, and many other advantages relative to the artificial tank cleaning. So many enterprises now are gradually adopting mechanical method of tank cleaning for oil tanks. Changing the way of high pressure jet, such as changing the flow parameters, medium properties, nozzle motion parameters, concluding the optimal cleaning parameters by comparison, which can effectively improve the efficiency of cleaning. This paper based on the fluid dynamics theory to establish machine storage tank and nozzle calculation model, and through the user-defined function (UDF) to describe the movement of the nozzle. Combined with the VOF model and k- turbulence model, simulating the flow field in the storage tank under different conditions. The results show that the optimal range of nozzle jet velocity is 28 m/s31 m/s; the optimal range of cleaning fluid temperature is 333 K338 K; the optimal range of rotating angular velocity of nozzle is 0.3 rpm-0.5 rpm in the same oil cleaning process.ABSTRACT

Keywords:

High Pressure Jet, Tank Cleaning, Numerical Simulation, Dynamic Grid

REFERENCES