REFERENCES

- [1] Shung, K. K., Cannata, J. M. and Zhou, Q. F., “Piezoelectric Materials for High Frequency Medical Imaging Applications: A Review,” Journal of Electroceramics, Vol. 19, No. 1, pp. 141�147 (2007). doi: 10.1007/s10832-007-9044-3

- [2] Marechal, P., Levassort, F., Holc, J., Tran-Huu-Hue, L.-P., Kosec, M. and Lethiecq, M., “High-Frequency Transducers Based on Integrated Piezoelectric Thick Films for Medical Imaging,” IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, Vol. 53, No. 8, pp. 1524�1533 (2006). doi: 10.1109/ TUFFC.2006.1665110

- [3] Wooh, S.-C. and Wang, J., “Nondestructive Characterization of Defects Using a Novel Hybrid Ultrasonic Array Sensor,” NDT & E International, Vol. 35, No. 3, pp. 155�163 (2002). doi: 10.1016/S0963-8695(01) 00038-X

- [4] Park, J., Je, Y., Lee, H. and Moon, W., “Design of an Ultrasonic Sensor for Measuring Distance and Detecting Obstacles,” Ultrasonics, Vol. 50, No. 3, pp. 340–346 (2010). doi: 10.1016/j.ultras.2009.10.013

- [5] Shin, S. W., Qureshi, A. R., Lee, J.-Y. and Yun, C. B., “Piezoelectric Sensor Based Nondestructive Active Monitoring of Strength Gain in Concrete,” Smart Materials and Structures, Vol. 17, No. 5, pp. 055002 (2008). doi: 10.1088/0964-1726/17/5/055002

- [6] Mo, Y., Tanaka, T., Inoue, K., Yamashita, K. and Suzuki, Y., “Front-End Processor Using BBD Distributed Delay-Sum Architecture for Micromachined Ultrasonic Sensor Array,” Journal of Microelectromechanical Systems, Vol. 12, No. 4, pp. 506�512 (2003). doi: 10.1109/JMEMS.2003.815840

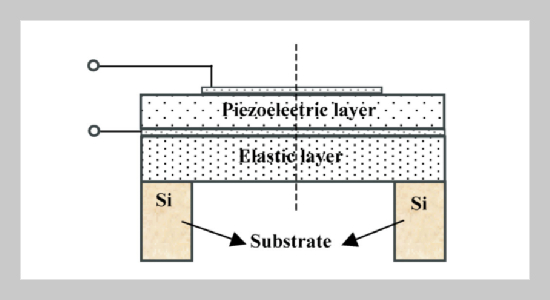

- [7] Akasheh, F., Myers, T., Fraser, J. D., Bose, S. and Bandyopadhyay, A., “Development of Piezoelectric Micromachined Ultrasonic Transducers,” Sensor and Actuators A: Physical, Vol. 111, No. 2-3, pp. 275�287 (2004). doi: 10.1016/j.sna.2003.11.022

- [8] Muralt, P., Ledermann, N., Baborowski, J., et al, “Piezoelectric Micromachined Ultrasonic Transducers Based on PZT Thin Film,” IEEE Transaction on Ultrasonics, Ferroelectrics, and Frequency Control, Vol. 52, No. 12, pp. 2276�2288 (2005). doi: 10.1109/ TUFFC.2005.1563270

- [9] Chong, A. C. M., Yang, F., Lam, D. C. C. and Tong, P., “Torsion and Bending of Micro-Scale Structures,” J. Mater. Res., Vol. 16, No. 4, pp. 1052�1058 (2001). doi: 10.1557/JMR.2001.0146

- [10] Fleck, N. A., Muller, G. M., Ashby, M. F., et al., “Strain Gradient Plasticity: Theory and Experiment,” Acta Metall Mater, Vol. 42, No. 2, pp. 475�487 (1994). doi: 10.1016/0956-7151(94)90502-9

- [11] Stolken, J. S. and Evans, A. G., “A Microbend Test Method for Measuring the Plasticity Length Scale,” Acta Mater, Vol. 46, No. 14, pp. 5109�5115 (1998). doi: 10.1016/S1359-6454(98)00153-0

- [12] Yang, F., Chong, A. C. M., Lam, D. C. C. and Tong, P., “Couple Stress Based Strain Gradient Theory for Elasticity,” International Journal of Solids and Structures, Vol. 39, No. 10, pp. 2731�2743 (2002). doi: 10.1016/ S0020-7683(02)00152-X

- [13] Mindlin, R. D. and Tiersten, H. F., “Effect of CoupleStresses in Linear Elasticity,” Arch Rational Mech Anal, Vol. 11, No. 1, pp. 415�448 (1962). doi: 10. 1007/BF00253946

- [14] Toupin, R. A., “Elastic Materials with Couple-Stresses,” Arch Rational Mech Anal, Vol. 11, No. 1, pp. 385�414 (1962). doi: 10.1007/BF00253945

- [15] Ke, L. L., Wang, Y. S., Yang, J. and Kitipornchai. S., “Free Vibration of Size-Dependent Mindlin Microplates Based on the Modified Couple Stress Theory,” Journal of Sound and Vibration, Vol. 331, No. 1, pp. 94�106 (2012). doi: 10.1016/j.jsv.2011.08.020

- [16] Roque, C. M. C., Fidalgo, D. S., Ferreira, A. J. M. and Reddy, J. N., “A Study of a Microstructure-Dependent Composite Laminated Timoshenko Beam Using a Modified Couple Stress Theory and a Meshless Method,” Composite Structures, Vol. 96, pp. 532�537 (2013). doi: 10.1016/j.compstruct.2012.09.011

- [17] Ding, J. N., Meng, Y. G. and Wen, S. Z., “Research of the Size Effect on Strength of Polysilicon MicroElectro-Mechanical Devices,” Journal of Mechanical Strength, Vol. 23, No. 4, pp. 385�388 (2001). (In Chinese)

- [18] Hwang, K., Qiu, X. M. and Jiang, H. Q., “Recent Advances in Strain Gradient Plasticity - I - Couple Stress Theory and SG Theory,” Journal of Mechanical Strength, Vol. 21, No. 2, pp. 81�87 (1999). (In Chinese)

- [19] Chen, S. H. and Wang, Z. Q., “Advances in Strain Gradient Theory,” Advances in Mechanics, Vol. 33, No. 2, pp. 207�216 (2003). (In Chinese)

- [20] Pradhan, K. K. and Chakraverty, S., “Free Vibration of Euler and Timoshenko Functionally Graded Beams by Rayleigh-Ritz Method,” Composites: Part B (2013). doi: 10.1016/j.compositesb.2013.02.027

- [21] Zhou, D., “Vibrations of Mindlin Rectangular Plates with Elastically Restrained Edges Using Static Timoshenko Beam Function with the Rayleigh-Ritz Method,” International Journal of Solids and Structures, Vol. 38, No. 32�33, pp. 5565�5580 (2001). doi: 10. 1016/S0020-7683(00)00384-X

- [22] Ilanko, S., “Comments on the Historical Bases of the Rayleigh and Ritz Methods,” Journal of Sound and Vibration, Vol. 319, pp. 731�733 (2009). doi: 10. 1016/j.jsv.2008.06.001

- [23] Grossi, R. O. and Albarracin. C. M., “Some Observation on the Application of the Rayleigh-Ritz Method,” Applied Acoustics, Vol. 62, No. 10, pp. 1171�1182 (2001). doi: 10.1016/S0003-682X(00)00097-9

- [24] Kang, X., Yang, F. J. and He, X. Y, “Nonlinearity Analysis of Piezoelectric Micro Machined Ultrasonic Transducers Based on Couple Stress Theory,” Acta Mechanica Sinica, Vol. 28, No. 1, pp. 104�111 (2012). doi: 10.1007/s10409-012-0019-5