REFERENCES

- [1] Selçuk Yildirim, Bettina Röcker, Marit Kvalvåg Pettersen, Julie Nilsen-Nygaard, Zehra Ayhan, Ramune Rutkaite, Tanja Radusin, Patrycja Suminska, Begonya Marcos, and Véronique Coma. Active Packaging Applications for Food. Comprehensive Reviews in Food Science and Food Safety, 17(1):165–199, jan 2018.

- [2] Simon Angelo Cichello. Oxygen absorbers in food preservation: a review. Journal of Food Science and Technology, 52(4):1889–1895, apr 2015.

- [3] P. V. Mahajan, F. A. S. Rodrigues, A. Motel, and A. Leonhard. Development of a moisture absorber for packaging of fresh mushrooms (Agaricus bisporous). Postharvest Biology and Technology, 48:408–414, 2008.

- [4] Kirtiraj K. Gaikwad, Suman Singh, and Abdellah Ajji. Moisture absorbers for food packaging applications. Environmental Chemistry Letters, 17(2):609–628, jun 2019.

- [5] S. Mohamad Jani, H. D. Rozman, A. Abusamah, Z. A. Mohd Ishak, and S. Rahim. Oil palm empty fruit bunch-polypropylene composites: the effect maleated polypropylene on the mechanical properties. Journal of Oil Palm Research, 18(December):260–271, 2006.

- [6] Mohammad R. Kaiser, Hazleen B. Anuar, Noorasikin B. Samat, and Shamsul B.Abdul Razak. Effect of processing routes on the mechanical, thermal and morphological properties of PLA-based hybrid biocomposite. Iranian Polymer Journal (English Edition), 22(2):123–131, 2013.

- [7] Reza Arjmandi, Azman Hassan, Khaliq Majeed, and Zainoha Zakaria. Rice Husk Filled Polymer Composites. International Journal of Polymer Science, 2015.

- [8] Jae Hyuk Jang, Seung Hwan Lee, Takashi Endo, and Nam Hun Kim. Dimension change in microfibrillated cellulose from different cellulose sources by wet disk milling and its effect on the properties of PVA nanocomposite. Wood Science and Technology, 49(3):495–506, may 2015.

- [9] N. H. Lazim and N. Samat. The influence of irradiated recycled polypropylene compatibilizer on the impact fracture behavior of recycled polypropylene/microcrystalline cellulose composites. Polymer Composites, 40(S1):E24–E34, jan 2019.

- [10] M. Y.M. Zuhri, S. M. Sapuan, and N. Ismail. Oil palm fibre reinforced polymer composites: A review. Progress in Rubber, Plastics and Recycling Technology, 25(4):233– 245, nov 2009.

- [11] Nina Graupner, Axel S. Herrmann, and Jörg Müssig. Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas. Composites Part A: Applied Science and Manufacturing, 40(6- 7):810–821, jul 2009.

- [12] Pramendra Kumar Bajpai, Inderdeep Singh, and Jitendra Madaan. Development and characterization of PLA-based green composites: A review. Journal of Thermoplastic Composite Materials, 27(1):52–81, jan 2014.

- [13] Paulo Peças, Hugo Carvalho, Hafiz Salman, and Marco Leite. Natural Fibre Composites and Their Applications: A Review. Journal of Composites Science, 2(4):66, nov 2018.

- [14] Layth Mohammed, M. N.M. Ansari, Grace Pua, Mohammad Jawaid, and M. Saiful Islam. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. International Journal of Polymer Science, 2015.

- [15] T. Gurunathan, Smita Mohanty, and Sanjay K. Nayak. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Composites Part A: Applied Science and Manufacturing, 77:1–25, jun 2015.

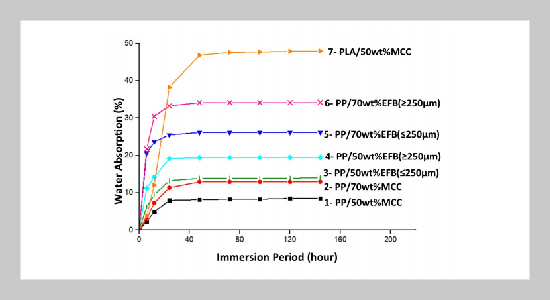

- [16] Asim Shahzad. Effects of water absorption on mechanical properties of hemp fiber composites. Polymer Composites, 33(1):120–128, jan 2012.

- [17] M. M. Thwe and K. Liao. Effects of environmental aging on the mechanical properties of bamboo-glass fiber reinforced polymer matrix hybrid composites. Composites Part A: Applied Science and Manufacturing, 33:43–52, 2002.

- [18] Noorasikin Samat, Robert Burford, Alan Whittle, and Mark Hoffman. The effects of water and frequency on fatigue crack growth rate in modified and unmodified polyvinyl chloride. Polymer Engineering and Science, 50(2):352–364, feb 2010.

- [19] H. P.S.Abdul Khalil, M. Siti Alwani, R. Ridzuan, H. Kamarudin, and A. Khairul. Chemical composition, morphological characteristics, and cell wall structure of Malaysian oil palm fibers. Polymer - Plastics Technology and Engineering, 47(3):273–280, mar 2008.

- [20] N. I. Zulkifli. Effect of maleated polypropylene and cellulose content on mechanical and thermal properties of recycled polypropylene/microcrystalline cellulose (rPP/MCC) Composites. PhD thesis, International Islamic University Malaysia (IIUM), 2015.

- [21] Noorasikin Samat, Nurul Hakimah Mohd Lazim, and Zahurin Halim. Dynamic mechanical and water absorption properties of microcrystalline cellulose reinforced polypropylene composites: The effect of unconventional irradiation route. IIUM Engineering Journal, 20(2):188–196, 2019.

- [22] Rajesh Gunti, A. V. Ratna Prasad, and A. V.S.S.K.S. Gupta. Mechanical and degradation properties of natural fiber-reinforced PLA composites: Jute, sisal, and elephant grass. Polymer Composites, 39(4):1125–1136, apr 2018.

- [23] Thabang H. Mokhothu and Maya Jacob John. Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydrate Polymers, 131:337–354, jun 2015.

- [24] Kirsi Leppänen, Seppo Andersson, Mika Torkkeli, Matti Knaapila, Nina Kotelnikova, and Ritva Serimaa. Structure of cellulose and microcrystalline cellulose from various wood species, cotton and flax studied by X-ray scattering. Cellulose, 16(6):999–1015, dec 2009.

- [25] N. Samat, N.N. Ghazali, Z. Ahmad, F. Ali, and Gombak Kuala Lumpur Selangor. Non-Acidic Method for Isolation of Microcrystalline Cellulose From Oil Palm Empty Fruit Bunch Fiber. International Journal of Engineering & Technology, 7(4.14):339–342, dec 2018.

- [26] Wissam Farhat, Richard A. Venditti, Martin Hubbe, Mohamed Taha, Frederic Becquart, and Ali Ayoub. A Review of Water-Resistant Hemicellulose-Based Materials: Processing and Applications. ChemSusChem, 10(2):305–323, 2017.

- [27] M. Jawaid, H. P.S. Abdul Khalil, P. Noorunnisa Khanam, and A. Abu Bakar. Hybrid Composites Made from Oil Palm Empty Fruit Bunches/Jute Fibres: Water Absorption, Thickness Swelling and Density Behaviours. Journal of Polymers and the Environment, 19(1):106–109, mar 2011.

- [28] H. D. Rozman, P. P. Lim, A. Abusamah, R. N. Kumar, H. Ismail, and Z. A. Mohd Ishak. The physical properties of oil palm empty fruit bunch (EFB) composites made from various thermoplastics. International Journal of Polymeric Materials and Polymeric Biomaterials, 44(1- 2):179–195, 1999.

- [29] N. Zulkifli, N. Samat, H. Anuar, and N. Zainuddin. Mechanical properties and failure modes of recycled polypropylene/microcrystalline cellulose composites. Materials & Design, 69:114–123, 2015.

- [30] Ayse Alemdar and Mohini Sain. Isolation and characterization of nanofibers from agricultural residues - Wheat straw and soy hulls. Bioresource Technology, 99(6):1664–1671, apr 2008.

- [31] Rachel Raïssa Ngono Mvondo, Pierre Meukam, Jena Jeong, Domingos De Sousa Meneses, and Elambo George Nkeng. Influence of water content on the mechanical and chemical properties of tropical wood species. Results in Physics, 7:2096–2103, jan 2017.