Dong Xiaohui This email address is being protected from spambots. You need JavaScript enabled to view it.1 1School of Mechanical Engineering, Yancheng Institute of Technology, Yancheng 224051, P.R. China

Received:

June 30, 2015

Accepted:

November 9, 2015

Publication Date:

March 1, 2016

Download Citation:

||https://doi.org/10.6180/jase.2016.19.1.07

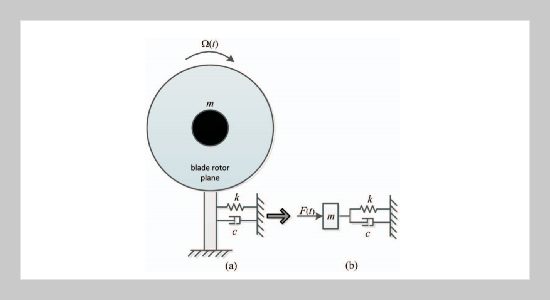

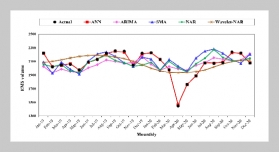

Based on an established axial vibration model of the wind turbine tower-nacelle system, the mechanical impedance method was applied to construct the mechanical network diagram for the axial vibration of the tower-nacelle system. Then, the axial free vibration and forced vibration of the system were analyzed theoretically with considering the displacement impedance or admittance as the transfer function. The analysis shows: for free vibration, the system performs damped vibration with light damping, the amplitude attenuates exponentially with light damping, the system returns to the equilibrium position directly with over-damping, and the system does not generate reciprocating vibration with critical damping; for forced vibration, the amplitude of the axial displacement response is related to the frequency ratio of rotation rate. The resonance frequency does not occur at the undamped natural frequency ω0. The peak value of the vibration triggered by blade mass imbalance shifts toward the high frequency direction along with the increase of damping ratio ξ, while the peak value of the vibration triggered by tower front spoiler and pneumatic imbalance shifts toward the low frequency direction along with the increase of ξ. If ξ> √2/2 , the amplitude frequency has no peak value, and resonance does not occur. The analysis provides a theoretical basis for the design and control of the wind turbine tower.ABSTRACT

Keywords:

Wind Turbine, Axial Vibration, Mechanical Impedance Method, Amplitude-frequency Characteristic

REFERENCES