Saranjit Singh This email address is being protected from spambots. You need JavaScript enabled to view it.1, A. K. Jha2 and S. Kumar1 1Department of Production Engineering Birla Institute of Technology Mesra Ranchi – 835 215, Jharkhand, India.

2Department of Mechanical Engineering, Institute of Technology Banaras Hindu University Varanasi – 221 005, U.P., India

Received:

November 7, 2003

Accepted:

April 6, 2004

Publication Date:

December 1, 2004

Download Citation:

||https://doi.org/10.6180/jase.2004.7.4.05

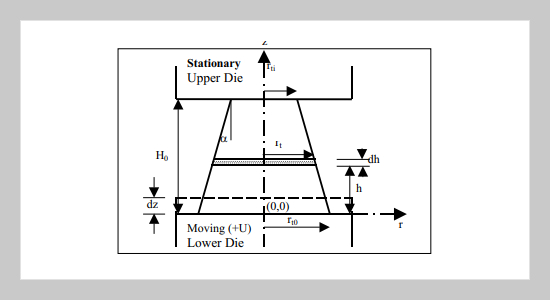

The upper bound method though an approximate energy method to obtain exact mathematical solutions is still preferred for analysis of metal forming problems. Although much work has been reported on the analysis of sinter-forging of preforms with simple generic shapes such as solid cylindrical discs and rectangular strips, the analysis of sinter-forging of truncated conical preform has not been considered. The present work deals with the upper bound analysis of axi-symmetric high-speed sinter-forging of truncated conical preforms under cold conditions by accounting for an exponential velocity field taking bulging and inertia effects. A generalized expression for average forging load has been established and the effect of taper angle, preform height and interfacial friction conditions at die-workpiece interface during deformation has been critically studied.ABSTRACT

Keywords:

High-Speed Sinter-Forging; Upper Bound; Truncated Conical Preform; Inertia Effect; Bulging

REFERENCES