Anshul Garg1 and Pushpendra Kumar Sharma This email address is being protected from spambots. You need JavaScript enabled to view it.2 1Research Scholar, Lovely Professional University, Phagwara, Punjab 144411, India

2Professor, Lovely Professional University, Phagwara, Punjab 144411, India

Received:

March 17, 2021

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.

Accepted:

May 17, 2021

Publication Date:

June 24, 2021

Download Citation:

||https://doi.org/10.6180/jase.202112_24(6).0018

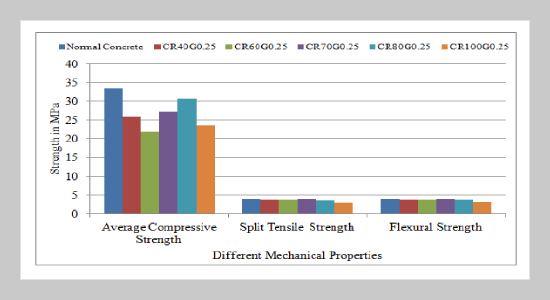

Scarcity of the construction resources such as money, labour, material, land and technology is creating a big chaos and so the nations are facing problems of low GDP’s. This research focuses on reuse of laboratory waste used aggregate and studying the mechanical properties of concrete with glass fiber and varying percentages of recycled aggregates. The study focuses on use of higher percentages of recycled aggregates and analyse optimum mix that can be used for structural applications by adding glass fibers without compromising the strength parameters. The behaviour of compressive, flexural and split tensile strength of concrete using glass fibers is studied where normal aggregates are partially replaced with recycled aggregates in proportions of 40%, 60%, 70%, 80% and 100% and usage of 0.25% glass fibers as addition by weight. After analyzing results it was observed that on addition of recycled aggregates strength decreases but mix designation CR80G0.25 (80% replacement of normal aggregates with recycled aggregates and addition of 0.25% of glass fibers) has least reduction 8.23% in compressive strength. Flexural and split tensile strength shows a reduction of 2.95% and 1.76% respectively for mix designation CR70G0.25 (70% replacement of normal aggregates with recycled aggregates and addition of 0.25% of glass fibers). This shows that Mix designation CR80G0.25 can be used for compression members like columns in buildings and Mix designation CR70G0.25 can be used in construction of beams and slabs.ABSTRACT

Keywords:

Glass fibers, Recycled, Aggregate, Compressive strength, Flexural Strength, Split tensile strength

[1] EHE-08, (2010) “Structural concrete instruction. 4th rev." Ministry of Development, Madrid Spain: [2] M. Safiuddin, U. J. Alengaram, M. M. Rahman, M. A. Salam, and M. Z. Jumaat, (2013) “Use of recycled concrete aggregate in concrete: a review" Journal of Civil Engineering and Management 19(6): 796–810. DOI:10.3846/13923730.2013.799093. [3] M. Etxeberria, E. Vázquez, A. Marí, and M. Barra Bizinotto, (2007) “Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete" Cement and Concrete Research 37: 735–742. DOI: 10.1016/j.cemconres.2007.02.002. [4] A. D. Buck, (1977) “Recycled concrete as a source of aggregate" Journal Proceedings 74(5): 212–219. [5] S. Frondistou-Yannas, (1977) “Waste concrete as aggregate for new concrete" Journal Proceedings 74(8): 373–376. [6] V. Malhotra, (1978) “Recycled concrete—a new aggregate" Canadian Journal of Civil Engineering 5: 42–52. DOI: 10.1139/l78-006. [7] T. C. Hansen and H. Narud, (1983) “Strength of recycled concrete made from crushed concrete coarse aggregate" Concrete international 5(1): 79–83. [8] R. Sri Ravindrarajah and C. T. Tam, (1985) “Properties of concrete made with crushed concrete as coarse aggregate" Magazine of concrete research 37(130): 29–38. [9] P. Sharma and P. Agrawal, (2018) “Green Concrete: A Sustainable Solution" International Journal of Computational Engineering Research 08(1): 40–43. [10] U. J. Alengaram, A. Salam, M. Z. Jumaat, F. F. Jaafar, and H. B. Saad, (2011) “Properties of high-workability concrete with recycled concrete aggregate" Materials Research 14(2): 248–255. [11] R. V. Silva, J. De Brito, and R. K. Dhir, (2018) “Freshstate performance of recycled aggregate concrete: A review" Construction and Building Materials 178: 19–31. [12] M. Tavakoli and P. Soroushian, (1996) “Strengths of recycled aggregate concrete made using field-demolished concrete as aggregate" Materials Journal 93(2): 178–181. [13] A. Batt and A. Garg, (2017) “Partial Replacement of Wood Ash with Ordinary Portland Cement and Foundry Sand as Fine Aggregate" Journal of Civil & Environmental Engineering 07: DOI: 10.4172/2165- 784X. 1000272. [14] R. Garg, A. and Islam, (2018) “Experimental studies on the strength of cement concrete with partial replacement of coarse aggregate with ceramic tiles and cement with silica fume" International Journal of Advance Research, Ideas and Innovations in Technology 4(5): 46–52. [15] J. Takagi, (1974) “Some Properties of glass fiber reinforced concrete" Special Publication 44: 93–112. [16] C. Vipulanandan and S. Mebarkia, (1996) “Flexural and Facture Properties of Glass Fiber Reinforced Polyester Polymer Concrete" Special Publication 166: 1–16. [17] F. Mwizerwa and A. Garg, (2017) “Experimental study on effects on properties of concrete with different colours of glass powder as a partial replacement of cement" International Journal of Civil Engineering and Technology 8: 1639–1644. [18] A. Garg, G. Mehta, and A. Mahajan, (2019) “Experimental study on behavior of coconut and hair fibre in concrete" Ecology, Environment and Conservation 25: 151–155. [19] A. Garg and P. Sharma, (2019) “A Critical Review on Behaviour of Glass Fiber Reinforced Concrete Using Recycled Aggregates" IOSR Journal of Engineering 1: 54–59. [20] A. Kumar and P. Sharma, (2019) “A Critical Review on Green and Sustainable Concrete Reusing Various Dismentaling Building Waste Materials" IOSR Journal of Engineering 1: 84–91. [21] IS:10262, (2009) “Proportioning-Guidelines. Bureau of Indian Standards" Bureau of Indian Standards.New Delhi, India: [22] IS:1199, (1959) “Methods of Sampling and Analysis of Concrete" Bureau of Indian Standards.New Delhi, India: [23] IS:516, (1959) “Methods of Tests for Strength of Concrete" Bureau of Indian Standards. New Delhi, India: [24] IS:5816, “Splitting Tensile Strength of Concrete-Method of Test" Bureau of Indian Standards. New Delhi, India:REFERENCES