Shu-Wei Chuang1, Fuh-Lin Lih2 and Jr-Ming Miao This email address is being protected from spambots. You need JavaScript enabled to view it.3 1Institute of Weapon Systems, Chung Cheng Institute of Technology, National Defense University, Taoyuan, Taiwan 335, R.O.C.

2Center of General Education, R.O.C. Military Academy, Kaohsiung, Taiwan 830, R.O.C.

3Department of Biomechatronic Engineering, National Pingtung University of Science and Technology, Pingtung, Taiwan 912, R.O.C.

Received:

April 23, 2012

Accepted:

May 30, 2012

Publication Date:

September 1, 2012

Download Citation:

||https://doi.org/10.6180/jase.2012.15.3.05

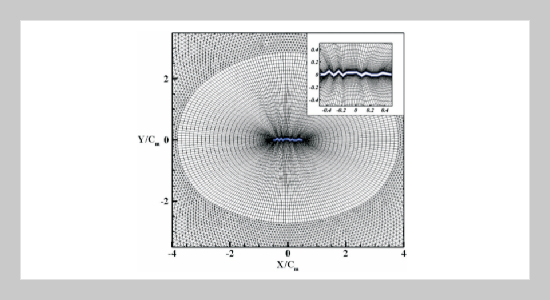

The effects of the Reynolds number and inclined angle of stroke plane on the generating lift and thrust forces of a flapping corrugated airfoil was studied by numerical simulations with dynamic deformable meshes. The chord Reynolds number (Re) based on the incoming airstream velocity is varied from 103 to 104 with interval of 103 . Two different inclined angles of stroke plane on the aerodynamic forces of corrugated airfoil were also considered. Due to the corrugated shape of dragonfly wings varied depending on the cross section location chosen, present tested profile of airfoil was selected from the mid-span of wing of an Aeshna cyanea dragonfly forewing. Unsteady flows over a corrugated thin airfoil and a flat-plate executing flapping motion are computed with time-dependent two-dimensional laminar incompressible Navier-Stokes equations. The dynamic mesh technique is applied to model the flow field of cyclical flapping motion of a corrugated airfoil under different combinations of pitch angle and stroke amplitude. Instant vorticity contours over a complete flapping cycle of a corrugated airfoil and a flat-plate clearly reveals the flow mechanisms for lift force generation are dynamic stall, rotational circulation, and wake capture. The thrust force is dominated by the formation of leading edge vortex (LEV) and trailing edge vortex (TEV) shedding downstream to form a reverse von Karman vortex. Results indicated that there is little difference on the aerodynamic force between corrugated airfoil and flat-plate under tested range of flapping frequency. The mean lift force coefficient of corrugated airfoil was enhanced with the increasing of Re. Visible changes in the mean lift force coefficient can be identified from the variation of inclined angle of stroke plane at a fixed Re. The critical products of reduced frequency and stroke amplitude to generate the positive mean thrust force output of a corrugated airfoil was given in present work.ABSTRACT

Keywords:

Bio-inspired MAV, Corrugated airfoil, CFD, Reynolds number, Inclined angle of stroke plane

REFERENCES