Ying-Haur Lee This email address is being protected from spambots. You need JavaScript enabled to view it.1 and Samuel H. Carpenter This email address is being protected from spambots. You need JavaScript enabled to view it.2 1Department of Civil Engineering Tamkang University Tamsui, Taipei, Taiwan 251, R.O.C.

2Department of Civil and Environmental Engineering, University of Illinois at Urbana-Champaign, 1206 Newmark CE Lab, 205 N. Mathews Ave., Urbana, IL 61801, U.S.A.

Received:

October 15, 2001

Accepted:

November 24, 2001

Publication Date:

December 1, 2001

Download Citation:

||https://doi.org/10.6180/jase.2001.4.4.07

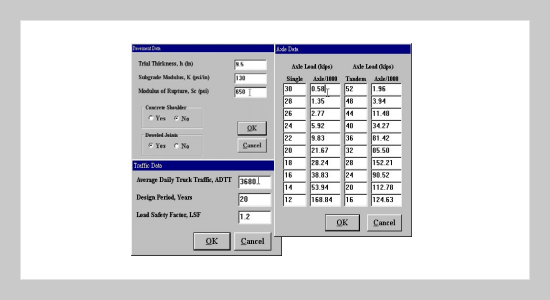

The primary objective of this study is to unveil the technical know how of the Portland Cement Association (PCA) pavement thickness design procedure. The PCA thickness design criteria are to limit the number of load repetitions based on both fatigue analysis and erosion analysis to prevent the first crack initiation due to critical edge stresses as well as to prevent pavement failures such as pumping, erosion of foundation, and joint faulting due to critical corner deflections. The PCA design equations have been implemented in a window-based computer program (PCAWIN) to facilitate verification against the well-known PCAPAV program. The PCAWIN program was designed to be highly user-friendly and thus came with many well-organized graphical interfaces, selection menus, and command buttons for easy use. Both English version and Chinese version of the program are available at the web site: http://teg.ce.tku.edu.tw. Many tentative modification alternatives including the reconsideration of design period and traffic, axle load distributions, temperature curling and moisture warping, modified equivalent stress calculation, the determination of equivalent stress factors, subbase and subgrade support, and design reliability are discussed.ABSTRACT

Keywords:

PCA, Concrete Pavements, Thickness Design, Fatigue Analysis, Equivalent Stress, Erosion Analysis, PCAWIN

REFERENCES