REFERENCES

- [1] S. A. Umoren, M. M. Solomon, I. B. Obot, and R. K. Suleiman, (2019) “A critical review on the recent studies on plant biomaterials as corrosion inhibitors for industrial metals" Journal of Industrial and Engineering Chemistry 76: 91–115. DOI: 10.1016/j.jiec.2019.03.057.

- [2] D. Kesavan, M. Gopiraman, and N. Sulochana, (2012) “Green inhibitors for corrosion of metals: a review" Chem. Sci. Rev. Lett 1(1): 1–8.

- [3] C. Verma, D. K. Verma, E. E. Ebenso, and M. A. Quraishi, (2018) “Sulfur and phosphorus heteroatomcontaining compounds as corrosion inhibitors: An overview" Heteroatom Chemistry 29(4): DOI: 10.1002/hc.21437.

- [4] S. Jayakumar, T. Nandakumar, M. Vadivel, C. Thinaharan, R. P. George, and J. Philip, (2020) “Corrosion inhibition of mild steel in 1MHCl using Tamarindus indica extract: electrochemical, surface and spectroscopic studies" Journal of Adhesion Science and Technology 34(7): 713–743. DOI: 10.1080/01694243.2019.1681156.

- [5] O. Sanni, A. Popoola, and O. Fayomi, (2018) “Enhanced corrosion resistance of stainless steel type 316 in sulphuric acid solution using eco-friendly waste product" Results in Physics 9: 225–230. DOI: 10.1016/j.rinp.2018.02.001.

- [6] M. P. Asfia, M. Rezaei, and G. Bahlakeh, (2020) “Corrosion prevention of AISI 304 stainless steel in hydrochloric acid medium using garlic extract as a green corrosion inhibitor: Electrochemical and theoretical studies" Journal of Molecular Liquids 315: DOI: 10.1016/j.molliq.2020.113679.

- [7] A. Fouda, M. Hegazi, and A. El-Azaly, (2019) “Henna extract as green corrosion inhibitor for carbon steel in hydrochloric acid solution" International Journal of Electrochemical Science 14(5): 4668–4682. DOI: 10.20964/2019.05.47.

- [8] S. J. H. M. Jessima, S. Subhashini, and J. Arulraj, (2020) “Sunova spirulina Powder as an Effective Environmentally Friendly Corrosion Inhibitor for Mild Steel in Acid Medium" Journal of Bio- and Tribo-Corrosion 6(3): DOI: 10.1007/s40735-020-00370-x.

- [9] O. Sanni, O. Fayomi, and A. Popoola, (2021) “Environmentally-friendly Inhibitor From Waste for Aluminium Corrosion in 0.5 M Sulphuric Acid Environment":

- [10] A. Fidrusli, Suryanto, and M. Mahmood. “Ginger extract as green corrosion inhibitor of mild steel in hydrochloric acid solution”. In: 290. 1. Cited by: 17; All Open Access, Bronze Open Access. 2018. DOI: 10.1088/1757-899X/290/1/012087.

- [11] J. Lohitkarn, P. Hemwech, R. Chantiwas, and M. Jariyaboon, (2021) “The Role of Cassava Leaf Extract as Green Inhibitor for Controlling Corrosion and Scale Problems in Cooling Water Systems" Journal of Failure Analysis and Prevention 21(3): 847–860. DOI: 10.1007/s11668-021-01121-x.

- [12] H. Hassannejad and A. Nouri, (2018) “Sunflower seed hull extract as a novel green corrosion inhibitor for mild steel in HCl solution" Journal of Molecular Liquids 254: 377–382. DOI: 10.1016/j.molliq.2018.01.142.

- [13] N. Odewunmi, S. Umoren, and Z. Gasem, (2015) “Watermelon waste products as green corrosion inhibitors for mild steel in HCl solution" Journal of Environmental Chemical Engineering 3(1): 286–296. DOI: 10.1016/j.jece.2014.10.014.

- [14] P. Mahalakshmi, S. Rajendran, G. Nandhini, S. Joycee, N. Vijaya, T. Umasankareswari, and N. Renuga Devi, (2020) “Inhibition of corrosion of mild steel in sea water by an aqueous extract of turmeric powder" International Journal of Corrosion and Scale Inhibition 9(2): 706–725. DOI: 10.17675/2305-6894-2020-9-2-20.

- [15] S. Sobri and N. Rahim, (2017) “Inhibitive effect of Cocon Nucifera L. (Coconut pulp) extract on mild steel acid corrosion" Jurnal Teknologi 79(5-3): 9–14. DOI: 10.11113/jt.v79.11320.

- [16] Food Crop Statistic, Department of Agriculture Malaysia. Website. http://www.doa.gov.my/.

- [17] O. O. Ezekiel, O. C. Aworh, J. C. du Preez, and L. Steyn, (2012) “Cultivation of Candida utilis on cassava peel hydrolysates for single-cell protein production" Journal of Food Science and Engineering 2(8): 452.

- [18] F. Sulaiman, M. Septiani, S. Aliyasih, and N. Huda, (2019) “Effectiveness of a cassava peel adsorbent on the absorption of copper (Cu2+) and zinc (Zn2+) metal ions" International Journal on Advanced Science, Engineering and Information Technology 9(4): 1296–1301. DOI: 10.18517/ijaseit.9.4.8990.

- [19] S. Mohd-Asharuddin, N. Othman, N. S. Mohd Zin, and H. A. Tajarudin. “A Chemical and Morphological Study of Cassava Peel: A PotentialWaste as Coagulant Aid”. In: 103. Cited by: 18; All Open Access, Gold Open Access, Green Open Access. 2017. DOI: 10.1051/matecconf/201710306012.

- [20] E. Ituen, O. Akaranta, and A. James, (2017) “Evaluation of performance of corrosion inhibitors using adsorption isotherm models: an overview" Chem. Sci. Int. J 18(1): 1–34.

- [21] N. Ayawei, S. S. Angaye, D. Wankasi, E. D. Dikio, et al., (2015) “Synthesis, characterization and application of Mg/Al layered double hydroxide for the degradation of congo red in aqueous solution" Open Journal of Physical Chemistry 5(03): 56.

- [22] N. Ayawei, A. N. Ebelegi, and D. Wankasi, (2017) “Modelling and Interpretation of Adsorption Isotherms" Journal of Chemistry 2017: DOI: 10.1155/2017/3039817.

- [23] G. Bekiaris, C. Peltre, S. T. Barsberg, S. Bruun, K. M. Sørensen, S. B. Engelsen, J. Magid, M. Hansen, and L. S. Jensen, (2020) “Three different Fourier-transform mid-infrared sampling techniques to characterize bioorganic samples" Journal of Environmental Quality 49(5): 1310–1321. DOI: 10.1002/jeq2.20106.

- [24] J. Lamaming, R. Hashim, O. Sulaiman, C. P. Leh, T. Sugimoto, and N. A. Nordin, (2015) “Cellulose nanocrystals isolated from oil palm trunk" Carbohydrate Polymers 127: 202–208. DOI: 10.1016/j.carbpol.2015.03.043.

- [25] S. Idris, S. Rosnah, M. Nor, M. Mokhtar, and S. Abdul Gani, (2020) “Physicochemical composition of different parts of cassava (Manihot esculenta crantz) plant" Food Research 4: 78–84. DOI: 10.26656/fr.2017.4(S1).S33.

- [26] A. Fidrusli, Suryanto, and M. Mahmood. “Ginger extract as green corrosion inhibitor of mild steel in hydrochloric acid solution”. In: 290. 1. Cited by: 17; All Open Access, Bronze Open Access. 2018. DOI: 10.1088/1757-899X/290/1/012087.

- [27] X. Li, S. Deng, T. Lin, X. Xie, and G. Du, (2018) “Cassava starch-sodium allylsulfonate-acryl amide graft copolymer as an effective inhibitor of aluminum corrosion in HCl solution" Journal of the Taiwan Institute of Chemical Engineers 86: 252–269. DOI: 10.1016/j.jtice.2018.03.002.

- [28] R. T. Loto, C. A. Loto, O. Joseph, and G. Olanrewaju, (2016) “Adsorption and corrosion inhibition properties of thiocarbanilide on the electrochemical behavior of high carbon steel in dilute acid solutions" Results in Physics 6: 305–314. DOI: 10.1016/j.rinp.2016.05.013.

- [29] T. Kawauchi, T. Kojima, H. Sakaguchi, and T. Iyoda, (2018) “Electrostatic Repulsion-Induced Desorption of Dendritic Viologen-Arranged Molecules Anchored on a Gold Surface through a Gold-Thiolate Bond Leading to a Tunable Molecular Template" Langmuir 34(22): 6420–6427. DOI: 10.1021/acs.langmuir.8b00858.

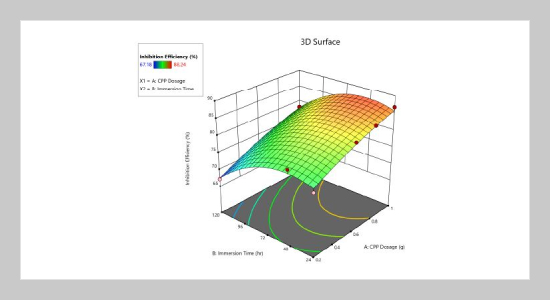

- [30] P. Kumari and M. Lavanya, (2021) “Optimization of Inhibition Efficiency of a Schiff Base on Mild Steel in Acid Medium: Electrochemical and RSM Approach" Journal of Bio- and Tribo-Corrosion 7(3): DOI: 10.1007/s40735-021-00542-3.

- [31] S. Greenland, S. J. Senn, K. J. Rothman, J. B. Carlin, C. Poole, S. N. Goodman, and D. G. Altman, (2016) “Statistical tests, P values, confidence intervals, and power: a guide to misinterpretations" European Journal of Epidemiology 31(4): 337–350. DOI: 10.1007/s10654-016-0149-3.

- [32] N. Hassan, S. M. Ali, A. Ebrahim, and H. El-Adwy, (2019) “Performance evaluation and optimization of Camellia sinensis extract as green corrosion inhibitor for mild steel in acidic medium" Materials Research Express 6(8): DOI: 10.1088/2053-1591/ab2376.

- [33] M. Benarioua, A. Mihi, N. Bouzeghaia, and M. Naoun, (2019) “Mild steel corrosion inhibition by Parsley (Petroselium Sativum) extract in acidic media" Egyptian Journal of Petroleum 28(2): 155–159. DOI: 10.1016/j.ejpe.2019.01.001.

- [34] B. Hafez, M. Mokhtar, H. Elmsellem, and H. Steli, (2019) “Environmentally friendly inhibitor of the corrosion of mild steel: Commercial oil of eucalyptus" International Journal of Corrosion and Scale Inhibition 8(3): 573–585. DOI: 10.17675/2305-6894-2019-8-3-8.

- [35] J. Rouquerol, F. Rouquerol, P. Llewellyn, G. Maurin, and K. S. Sing. Adsorption by Powders and Porous Solids: Principles, Methodology and Applications: Second Edition. Cited by: 521. 2013, 1–626. DOI: 10.1016/C2010-0-66232-8.

- [36] H. K. Boparai, M. Joseph, and D. M. O’Carroll, (2011) “Kinetics and thermodynamics of cadmium ion removal by adsorption onto nano zerovalent iron particles" Journal of Hazardous Materials 186(1): 458–465. DOI: 10.1016/j.jhazmat.2010.11.029.

- [37] M. Ali Asaad, N. N. Sarbini, A. Sulaiman, M. Ismail, G. F. Huseien, Z. Abdul Majid, and P. Bothi Raja, (2018) “Improved corrosion resistance of mild steel against acid activation: Impact of novel Elaeis guineensis and silver nanoparticles" Journal of Industrial and Engineering Chemistry 63: 139–148. DOI: 10.1016/j.jiec.2018.02.010.