REFERENCES

- [1] Alicia N. Fraga, Vera A. Alvarez, Analía Vázquez, and Orlando De La Osa. Relationship between dynamic mechanical properties and water absorption of unsaturated polyester and vinyl ester glass fiber composites. Journal of Composite Materials, 37(17):1553–1574, 2003.

- [2] Sugiman Sugiman, I. Ketut Pradnyana Putra, and Paryanto Dwi Setyawan. Effects of the media and ageing condition on the tensile properties and fracture toughness of epoxy resin. Polymer Degradation and Stability, 134:311–321, 2016.

- [3] Sudirman, M. Anggaravidya, E. Budianto, and I. Gunawan. Synthesis and Characterization of Polyester- Based Nanocomposite. Procedia Chemistry, 4:107–113, 2012.

- [4] Rajendran Baskaran, Muthusamy Sarojadevi, and Chinnaswamy Thangavel Vijayakumar. Mechanical and thermal properties of unsaturated polyester/calcium carbonate nanocomposites. Journal of Reinforced Plastics and Composites, 30(18):1549–1556, 2011.

- [5] Ritu Jain, A. K. Narula, and Veena Choudhary. Studies on epoxy/calcium carbonate nanocomposites. Journal of Applied Polymer Science, 114(4):2161–2168, 2009.

- [6] Fan-Long Jin and Soo-Jin Park. Interfacial toughness properties of trifunctional epoxy resins/calcium carbonate nanocomposites. Materials Science and Engineering: A, 475(1-2):190–193, 2008.

- [7] NH Mohd Zulfli, A Abu Bakar, and WS Chow. Mechanical and thermal properties improvement of nano calcium carbonate-filled epoxy/glass fiber composite laminates. High Performance Polymers, 26(2):223–229, 2014.

- [8] Hongwei He, Kaixi Li, Jianlong Wang, Guohua Sun, Yanqiu Li, and Jianlong Wang. Study on thermal and mechanical properties of nano-calcium carbonate/ epoxy composites. Materials and Design, 32(8-9):4521–4527, 2011.

- [9] Volkan Eskizeybek, Hasan Ulus, Halil B Kaybal, Ömer S. ¸Sahin, and Ahmet Avcı. Static and dynamic mechanical responses of CaCO3 nanoparticle modified epoxy/carbon fiber nanocomposites. Composites Part B: Engineering, 140(July 2017):223–231, 2018.

- [10] R. Baskaran, M. Sarojadevi, and C. T. Vijayakumar. Unsaturated polyester nanocomposites filled with nano alumina. Journal of Materials Science, 46(14):4864–4871, 2011.

- [11] Vinay Kumar Patel and Anil Dhanola. Influence of CaCO3, Al2O3, and TiO2 microfillers on physicomechanical properties of Luffa cylindrica/polyester composites. Engineering Science and Technology, an International Journal, 19(2):676–683, 2016.

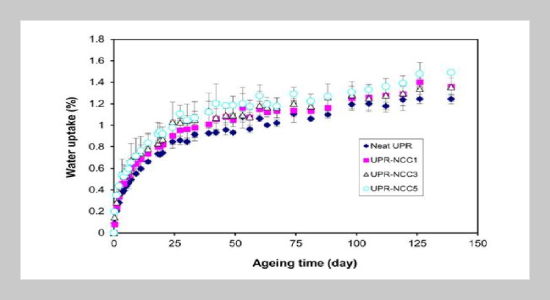

- [12] Sugiman Sugiman, Paryanto Dwi Setyawan, Maryudi Maryudi, and Sutikno Madnasri. Water absorption, tensile, flexural and impact properties of aged bamboo fibre/nano CaCO3-modified unsaturated polyester composites. Journal of Applied Science and Engineering (Taiwan), 24(2):239–251, 2021.

- [13] N. Rull, R. P. Ollier, G. Francucci, E. S. Rodriguez, and V. A. Alvarez. Effect of the addition of nanoclays on the water absorption and mechanical properties of glass fiber/up resin composites. Journal of Composite Materials, 49(13):1629–1637, 2015.

- [14] Plate Materials, Electrical Insulating Materials, Polymer Matrix, Composite Materials, and Plastic Specimens. Standard Test Method for Tensile Properties of Plastics 1. ASTM Standards, 08(January 2004):1–15, 2006.

- [15] Thermoplastics Molding and Extrusion Materials. Standard Test Methods for Determining the Izod Pendulum Impact Resistance of. Methods, 08(January):1–20, 2004.

- [16] ASTM D570. Standard Test Method for Water Absorption of Plastics, volume 98. ASTM International, Pennsylvania, 2014.

- [17] O. L.S. Alsina, L. H. de Carvalho, F. G.Ramos Filho, and J. R.M. D’Almeida. Immersion temperature effects on the water absorption behavior of hybrid lignocellulosic fiber reinforced-polyester matrix composites. Polymer- Plastics Technology and Engineering, 46(5):515–520, 2007.

- [18] H. Alamri and I. M. Low. Effect of water absorption on the mechanical properties of nanoclay filled recycled cellulose fibre reinforced epoxy hybrid nanocomposites. Composites Part A: Applied Science and Manufacturing, 44(1):23–31, 2013.

- [19] Olesja Starkova, Swetha Chandrasekaran, Thea Schnoor, Jevgenijs Sevcenko, and Karl Schulte. Anomalous water diffusion in epoxy/carbon nanoparticle composites. Polymer Degradation and Stability, 164:127–135, 2019.

- [20] Hadi Khoramishad and Omid Alizadeh. Effects of silicon carbide nanoparticles and multi-walled carbon nanotubes on water uptake and resultant mechanical properties degradation of polymer nanocomposites immersed in hot water. Polymer Composites, 39:E883–E890, 2018.

- [21] Guillermina Capiel, Luis A Miccio, Pablo E Montemartini, and Gustavo A Schwartz. Water diffusion and hydrolysis effect on the structure and dynamics of epoxyanhydride networks. Polymer Degradation and Stability, 143:57–63, 2017.

- [22] Sugiman Sugiman, Salman Salman, and Maryudi Maryudi. Effects of volume fraction on water uptake and tensile properties of epoxy filled with inorganic fillers having different reactivity to water. Materials Today Communications, 24:101360, 2020.

- [23] Sugiman Sugiman and Salman Salman. Hygrothermal effects on tensile and fracture properties of epoxy filled with inorganic fillers having different reactivity to water. Journal of Adhesion Science and Technology, 33(7):691–714, apr 2019.

- [24] Hongwei He, Jingjing Yang,Wei Huang, and Muhua Cheng. Influence of nano-calcium carbonate particles on the moisture absorption and mechanical properties of epoxy nanocomposite. Advances in Polymer Technology, 37(4):1022–1027, 2018.

- [25] Jiming Zhou and James P. Lucas. Hygrothermal effects of epoxy resin. Part II: Variations of glass transition temperature. Polymer, 40(20):5513–5522, 1999.

- [26] Dionysis E Mouzakis, Helen Zoga, and Costas Galiotis. Accelerated environmental ageing study of polyester/glass fiber reinforced composites (GFRPCs). Composites Part B: Engineering, 39(3):467–475, 2008.

- [27] Emile S. Greenhalgh. Failure analysis and fractography of polymer composites. Woodhead Publishing Limited, Oxford, 2009.

- [28] Guangshun Wu, Lichun Ma, Yuwei Wang, Li Liu, and Yudong Huang. Interfacial properties and impact toughness of methylphenylsilicone resin composites by chemically grafting POSS and tetraethylenepentamine onto carbon fibers. Composites Part A: Applied Science and Manufacturing, 84:1–8, 2016.