REFERENCES

- [1] Kai Zhang, Fangxin Wang, Wenyan Liang, Zhenqing Wang, Zhiwei Duan, and Bin Yang. Thermal and mechanical properties of bamboo fiber reinforced epoxy composites. Polymers, 8(6), 2018.

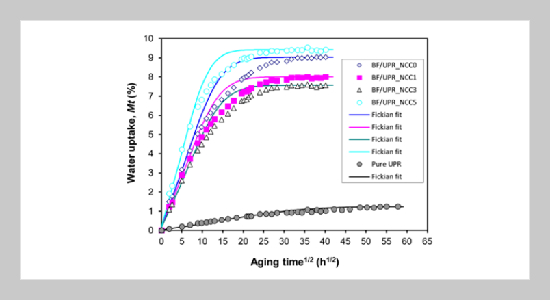

- [2] Sugiman Sugiman, Paryanto Dwi Setyawan, and Buan Anshari. Water absorption and impact strength of alkali-treated bamboo fiber/polystyrene-modified unsaturated polyester composites. Journal of Applied Science and Engineering, 23(1):9–20, 2020.

- [3] D. T. Tran, D. M. Nguyen, C. N. Ha Thuc, and T. T. Dang. Effect of coupling agents on the properties of bamboo fiber-reinforced unsaturated polyester resin composites. Composite Interfaces, 20(5):343–353, jul 2013.

- [4] Wendi Liu, Tingting Chen, Xiaoyun Wen, Renhui Qiu, and Xincong Zhang. Enhanced mechanical properties and water resistance of bamboo fiber–unsaturated polyester composites coupled by isocyanatoethyl methacrylate. Wood Science and Technology, 48(6):1241– 1255, 2014.

- [5] Pradeep K Kushwaha and Rakesh Kumar. Influence of chemical treatments on the mechanical and water absorption properties of bamboo fiber composites. Journal of Reinforced Plastics and Composites, 30(1):73–85, jan 2011.

- [6] Hatem Alamri and It Meng Low. Effect of water absorption on the mechanical properties of nanoclay filled recycled cellulose fibre reinforced epoxy hybrid nanocomposites. Composites Part A: Applied Science and Manufacturing, 44:23–31, 2013.

- [7] T. P. Mohan and K. Kanny. Chemical treatment of sisal fiber using alkali and clay method. Composites Part A: Applied Science and Manufacturing, 43(11):1989–1998, nov 2012.

- [8] A Alhuthali, I. M. Low, and C. Dong. Characterisation of the water absorption, mechanical and thermal properties of recycled cellulose fibre reinforced vinyl-ester eco-nanocomposites. Composites Part B: Engineering, 43(7):2772–2781, 2012.

- [9] H Alamri and I M Low. Effect of water absorption on the mechanical properties of nano-filler reinforced epoxy nanocomposites. Materials and Design, 42:214– 222, 2012.

- [10] Ritu Jain, A. K. Narula, and Veena Choudhary. Studies on epoxy/calcium carbonate nanocomposites. Journal of Applied Polymer Science, 114(4):2161–2168, nov 2009.

- [11] Rajendran Baskaran, Muthusamy Sarojadevi, and Chinnaswamy Thangavel Vijayakumar. Mechanical and thermal properties of unsaturated polyester/calcium carbonate nanocomposites. Journal of Reinforced Plastics and Composites, 30(18):1549–1556, sep 2011.

- [12] Fan Long Jin and Soo Jin Park. Interfacial toughness properties of trifunctional epoxy resins/calcium carbonate nanocomposites. Materials Science and Engineering A, 475(1-2):190–193, feb 2008.

- [13] N. H.Mohd Zulfli, A. Abu Bakar, and W. S. Chow. Mechanical and thermal properties improvement of nano calcium carbonate-filled epoxy/glass fiber composite laminates. High Performance Polymers, 26(2):223–229, mar 2014.

- [14] Hongwei He, Kaixi Li, Jianlong Wang, Guohua Sun, Yanqiu Li, and Jianlong Wang. Study on thermal and mechanical properties of nano-calcium carbonate/epoxy composites. Materials and Design, 32(8- 9):4521–4527, sep 2011.

- [15] Volkan Eskizeybek, Hasan Ulus, Halil B. Kaybal, Ömer S. ¸Sahin, and Ahmet Avcı. Static and dynamic mechanical responses of CaCO3 nanoparticle modified epoxy/carbon fiber nanocomposites. Composites Part B: Engineering, 140:223–231, 2018.

- [16] Bahrum Prang Rocky and Amanda J Thompson. Production of natural bamboo fibers-1: experimental approaches to different processes and analyses. Journal of the Textile Institute, 109(10):1381–1391, oct 2018.

- [17] Cuicui Wang, Wei Song, Haitao Cheng, Xuefei Yu, Wenyan Li, and Shuangbao Zhang. Dipping Modification with Nano-CaCO3 to Improve Tensile Properties of Individual Bamboo Fiber for Developing Bamboo–Plastic Composite. Journal of Natural Fibers, 13(6):737–748, nov 2016.

- [18] Cuicui Wang, Ge Wang, Haitao Cheng, Shuangbao Zhang, Lee M. Smith, and Sheldon Q. Shi. CaCO3 in situ treated bamboo pulp fiber reinforced composites obtained by vacuum-assisted resin infusion. Wood Science and Technology, 51(3):571–584, may 2017.

- [19] Sugiman Sugiman, Paryanto D Setyawan, and Buan Anshari. Effects of alkali treatment of bamboo fibre under various conditions on the tensile and flexural properties of bamboo fibre/polystyrene-modified unsaturated polyester composites. Journal of Engineering Science and Technology, 14(1):27–47, 2019.

- [20] Ayman M. Atta, Hamad A. Al-Lohedan, Abdelrahman O. Ezzat, and Sami A. Al-Hussain. Characterization of superhydrophobic epoxy coatings embedded by modified calcium carbonate nanoparticles. Progress in Organic Coatings, 101:577–586, 2016.

- [21] S Sugiman, P D Setyawan, and B Anshari. Effect of fiber length on the mechanical properties and water absorption of bamboo fiber/polystyrene-modified unsaturated polyester composites. In IOP Conference Series: Materials Science and Engineering, volume 532. Institute of Physics Publishing, 2019.

- [22] ASTM D3039/D3039M. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. Technical report, ASTM International, Pennsylvania, 2000.

- [23] ASTM D790-03. Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulation Materials. Technical report, ASTM International, Pennsylvania, 2003.

- [24] ASTM D256-10. Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. Technical report, ASTM International, Pennsylvania, 2002.

- [25] ASTM D638-14. Standard Test Method for Tensile Properties of Plastics. Technical report, ASTM International, Pennsylvania, 2003.

- [26] J Crank. The Mathematics of Diffusion. 2nd ed., c edition, 1975.

- [27] Hongwei He, Jingjing Yang, Wei Huang, and Muhua Cheng. Influence of Nano-Calcium Carbonate Particles on the Moisture Absorption and Mechanical Properties of Epoxy Nanocomposite. Advances in Polymer Technology, 37(4):1022–1027, jun 2018.

- [28] Peerapan Dittanet, Raymond A. Pearson, and Paisan Kongkachuichay. Thermo-mechanical behaviors and moisture absorption of silica nanoparticle reinforcement in epoxy resins. International Journal of Adhesion and Adhesives, 78:74–82, oct 2017.

- [29] M. Paauw and A. Pizzi. A FT-IR analysis method for simple unsaturated polyesters. Journal of Applied Polymer Science, 42(5):1377–1384, mar 1991.

- [30] Chengyu Wang, Cheng Piao, Xianglin Zhai, F. Neal Hickman, and Jian Li. Synthesis and characterization of hydrophobic calcium carbonate particles via a dodecanoic acid inducing process. Powder Technology, 198(1):131–134, feb 2010.

- [31] Allan C. Manalo, Evans Wani, Noor Azwa Zukarnain, Warna Karunasena, and Kin Tak Lau. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fibre-polyester composites. Composites Part B: Engineering, 80:73–83, 2015.

- [32] Z. N. Azwa, B. F. Yousif, A. C. Manalo, and W. Karunasena. A review on the degradability of polymeric composites based on natural fibres, 2013.

- [33] Hongyan Chen, Menghe Miao, and Xin Ding. Influence of moisture absorption on the interfacial strength of bamboo/vinyl ester composites. Composites Part A: Applied Science and Manufacturing, 40(12):2013–2019, dec 2009.

- [34] H N Dhakal, Z Y Zhang, and M. O.W. Richardson. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Composites Science and Technology, 67(7-8):1674– 1683, 2007.

- [35] Vijay Baheti, Jiri Militky, Rajesh Mishra, and B. K. Behera. Thermomechanical properties of glass fabric/epoxy composites filled with fly ash. Composites Part B: Engineering, 85:268–276, oct 2015.

- [36] H. Alamri, I. M. Low, and Z. Alothman. Mechanical, thermal and microstructural characteristics of cellulose fibre reinforced epoxy/organoclay nanocomposites. Composites Part B: Engineering, 43(7):2762–2771, oct 2012.

- [37] Sugiman Sugiman, M. Hulaifi Gozali, and Paryanto Dwi Setyawan. Hygrothermal effects of glass fiber reinforced unsaturated polyester resin composites aged in steady and fluctuating conditions. Advanced Composite Materials, 28(1):87–102, jan 2019.

- [38] Shao Yun Fu, Xi Qiao Feng, Bernd Lauke, and Yiu Wing Mai. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Composites Part B: Engineering, 39(6):933–961, 2008.

- [39] Sugiman Sugiman, Salman Salman, and Maryudi Maryudi. Effects of volume fraction on water uptake and tensile properties of epoxy filled with inorganic fillers having different reactivity to water. Materials Today Communications, 24, 2020.

- [40] Sultan Öztürk. The effect of fibre content on the mechanical properties of hemp and basalt fibre reinforced phenol formaldehyde composites. Journal of Materials Science, 40(17):4585–4592, sep 2005.

- [41] Lingyu Sun, Ronald F Gibson, Faramarz Gordaninejad, and Jonghwan Suhr. Energy absorption capability of nanocomposites: A review, nov 2009.