Manjunath S. P.1, Prakash Binnal This email address is being protected from spambots. You need JavaScript enabled to view it.1, Rajashekhara S. This email address is being protected from spambots. You need JavaScript enabled to view it.1, and Jagadish Patil2 1Department of Chemical Engineering, Siddaganga Institute of Technology, Tumakuru-572103, Karnataka, India

2Department of Chemical Engineering, RV College of Engineering, Bangalore, Karnataka, India

Received:

December 11, 2019

Copyright The Author(s). This is an open access article distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are cited.

Accepted:

July 7, 2020

Publication Date:

December 1, 2020

Download Citation:

||https://doi.org/10.6180/jase.2020_23(4).0017

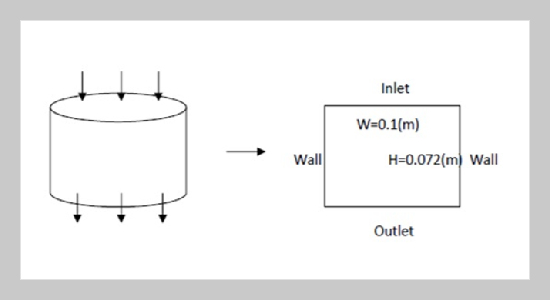

Zeolite Socony Mobil-5 (ZSM-5) is a synthetic Aluminium silicate zeolite belonging to the pentasil family of zeolite. The vertices are Al or Si and an O is assumed to be bonded between the vertices. In the present work, ZSM-5 was prepared by using Colloidal Silica and sodium aluminate as silicon and aluminium sources respectively. Since ZSM-5 acts as catalyst even at prolonged high temperature, the ZSM-5 is used for the Selective Catalytic Reduction of (SCR) of NOx in the exhaust pipe of diesel engine. A thin film of ZSM-5 was developed on the metal sheet by hydrothermal method forms a Selective catalytic reduction (SCR) catalyst of plate type of structure. The characterization of SCR catalyst is carried by subjecting to X-ray diffraction, BET test,erosion test. The surface area per unitv weight for uncalcined sample was 40.635 m2/g. The X-ray diffraction shows that the topology of the prepared silicate-1. The SCR catalytic converter was modeled using COMSOL Multiphysics software. The reactor modeling gave the result of concentration profile of ammonia, NOx gases, velocity profile and pressure profile along the reactor.ABSTRACT

Keywords:

ZSM-5 catalyst, SCR catalyst, NOx

REFERENCES